February 28, 2022

Rep. Kim Schrier Visits AJAC ApprenticesLast week, Congresswoman Dr. Kim Schrier contacted AJAC to learn more about our training programs in the 8th congressional district. She wanted an opportunity to meet apprentices who have excelled…

Read More

December 8, 2021

Workforce Training Remains Top Priority During Employer RoundtableNearly two years ago before the start of the pandemic, AJAC held its last in-person employer roundtable in Snohomish County. Since then, a dramatic shift in workforce development and skill…

Read More

November 9, 2021

Washington State Invests $3.8 Million in Aerospace Apprenticeship Expansion—AJAC Awarded $1.3 MillionAJAC is thrilled to announce we are the recipients of $1.3 million in grant funding through the Washington State Department of Labor & Industries’ “Aerospace Workforce Development Expansion” Grant.…

Read More

July 19, 2021

AJAC Trains Opportunity Youth for Manufacturing CareersBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

February 5, 2021

AJAC Talks Food Processing on New PodcastAJAC’s Regional Program Manager, Heather Collins, and Manufacturing Academy instructor, Stephen Matczak, sat down with Michelle Smith from the South Central Workforce Council to talk about AJAC’s exciting new apprenticeship…

Read More

January 21, 2021

AJAC Launches New CNC Programmer ApprenticeshipThe Aerospace Joint Apprenticeship Committee (AJAC) is excited to offer a new CNC Programmer Apprenticeship this spring! This program combines on-the-job training (OJT) with evening classes one night a week. AJAC…

Read More

December 22, 2020

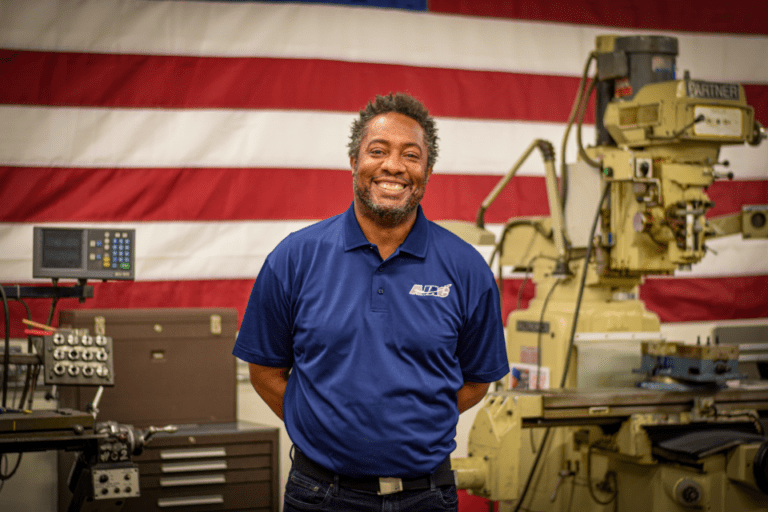

5 Questions with Lonnie FranklinWhat was the last experience that made you a stronger person? Making the move back to Seattle was something that made me a stronger person. Moving and going through a…

Read More

December 7, 2020

5 Questions with Priscilla JohnsonWhat will your new role at AJAC include? My role here at AJAC will be teaching the Manufacturing Academy pre-apprenticeship program. I will be providing instructional training for individuals that…

Read More

November 19, 2020

New Machine Operator Apprenticeship Launches in Yakima County for Food ManufacturersNo-cost training to launch this spring to upskill machine operators through registered apprenticeship YAKIMA, WA-November 19, 2020 – Over the next 10 years, 596 food-processing employees across Washington State will…

Read More

November 17, 2020

Free Online Mentorship Matters Training December 3rdMaximize Your Mentoring Effectiveness Having a structured mentorship system is a key component of an effective workforce development strategy. Never has this been more critical than today, with the vast…

Read More

November 12, 2020

One-on-One with Evan Thomas, AJAC Machinist GraduateTo celebrate National Apprenticeship Week 2020, AJAC sat down with former machinist graduate, Evan Thomas, for a candid interview about his apprenticeship experience. Our 24-minute conversation covered a wide variety…

Read More

July 28, 2020

Supporting Kent Manufacturers During COVID-19The Aerospace Joint Apprenticeship Committee (AJAC), Kent Valley Economic Development, City of Kent, Port of Seattle, and Green River College have partnered to support Kent manufacturers and their employees during…

Read More

June 19, 2020

Congratulations to the AJAC Class of 2020AJAC’s annual graduation ceremony at the Museum of Flight was postponed this year due to the COVID-19 global pandemic. Although we will celebrate all of our graduates during the 2021…

Read More

May 28, 2020

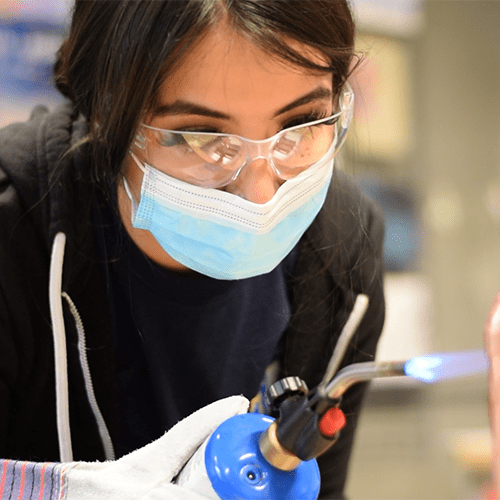

Meet Rachel, AJAC’s New Maintenance Technician ApprenticeMeet Rachel Bertapelle, one of 19 AJAC Industrial Maintenance Technician apprentices at Agri Beef in Toppenish, Washington. Rachel enrolled in AJAC’s 8,000 hour program this past winter and is now…

Read More

May 27, 2020

AJAC To Offer New Low-Cost, Short-Term Trainings This July!New Lost-Cost, Short-Term Trainings From AJAC AJAC is excited to announce this July we will offer three consecutive short-term trainings at our Advanced Manufacturing Prep Training Center in Kent, Washington.…

Read More

April 14, 2020

Letter from AJAC’s Executive Director on COVID-19During these unprecedented times, AJAC understands the disruption this crisis has caused in many lives. Our top priority is to ensure apprentices can continue to learn and instructors are able…

Read More

February 26, 2020

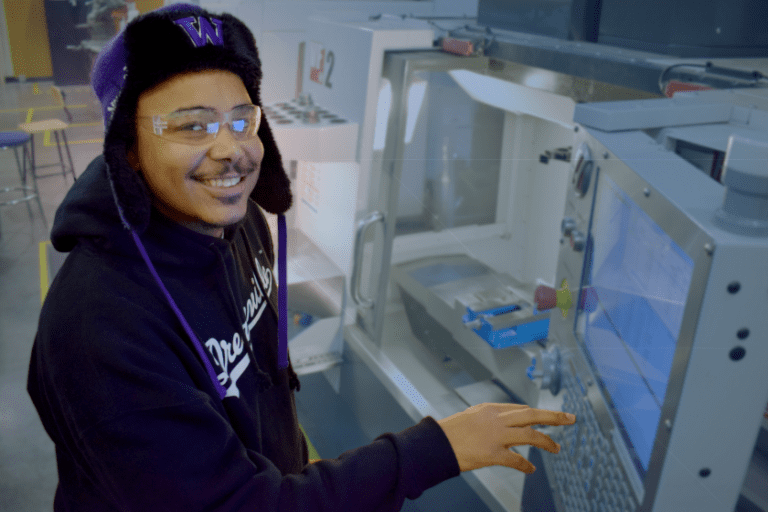

Our Mission. Their Story.Meet LaDante Weems—a formerly incarcerated youth and now graduate of the AJAC Juvenile Rehabilitation Manufacturing Academy program—tells his story on becoming a full-time employee at Tech Marine. We at AJAC…

Read More

January 31, 2020

AJAC Provides Apprenticeship Preparation Program For High School StudentsAJAC is launching a new Manufacturing Academy program in Federal Way through a partnership with the Federal Way Boys & Girls Club, Truman High School and a grant from Aspen…

Read More

December 12, 2019

Meet Heather, AJAC’s New Regional Program ManagerMeet Heather Collins, AJAC new Regional Program Manager for central Washington State. Heather comes to AJAC with a breadth of experience in program and business development including work in the…

Read More

December 10, 2019

Selene’s Redemption SongSelene Castro is no stranger to adversity. She has been fighting an uphill battle for years and while some would crumble under the pressure, it is has left her strong…

Read More

November 5, 2019

New Grants & Partnerships | Fall 2019Below are the new grants AJAC has been awarded over the last 3 months and the partnerships we have forged with local and national organizations. City of Seattle Office of…

Read More

October 31, 2019

AJAC Wins Seattle Business Magazine Community AwardOn October 24th, Seattle Business Magazine hosted an event honoring 15 visionary enterprises. AJAC (Aerospace Joint Apprenticeship Committee) was one of the establishments honored and wound up taking home the…

Read More

October 25, 2019

The Full Journey: From High School Apprentice to Adult ApprenticeshipChristian Gray has never been a person who enjoys wasting his time. Christian has always felt mature. He thrived at homeschooling because his mom would focus more on the…

Read More

October 25, 2019

AJAC Joins Movement to Get More Women Into ApprenticeshipsThe Aerospace Joint Apprenticeship Committee (AJAC) recently partnered with the Wisconsin Regional Training Partnership (WRTP) on a multi-state effort to encourage more women to enter into technical apprenticeship programs. WRTP…

Read More

October 8, 2019

MFG Day (Manufacturing Day) 2019 | AJAC & Machinists Inc.Take a tour of Machinist Inc in Seattle, Washington as the Aerospace Joint Apprenticeship Committee (AJAC) and Hazen High School (Renton School District) celebrate National Manufacturing Day (MFG Day) 2019.…

Read More

September 23, 2019

Manufacturing Academy Students Develop Financial Stability Through New Wells Fargo PartnershipThe Wells Fargo Foundation, established in the U.S. as a registered 501(c)(3) charitable organization in 1980, is the company’s primary philanthropic funding arm. In 2018, the foundation donated nearly half…

Read More

July 11, 2019

2019 Washington Youth Apprenticeship Signing DayOn June 28, 2019, nearly 100 newly registered Youth Apprentices from across Washington State celebrated the beginning of their apprenticeship at the ShoWare Center in Kent, Washington. Signing Day brought…

Read More

June 18, 2019

AJAC Graduates 79 Apprentices from 48 CompaniesOn June 14, 2019, the Aerospace Joint Apprenticeship Committee graduated 79 registered apprentices representing 48 companies from across Washington State. The apprentices were joined by their family, friends, and colleagues…

Read More

June 6, 2019

An Ordinary Teenager in an Extraordinary ApprenticeshipIt’s six in the morning at Tool Gauge, a Tacoma, Washington manufacturer that creates complex, high-quality plastic and metal parts and assemblies for the global aerospace industry. In walks a…

Read More

March 28, 2019

Introduction to Apprenticeships: PodcastThe South Central Workforce Council recently interviewed AJAC’s Director of Youth Apprenticeship, Bri Durham for their podcast “South Central Works.” In the podcast, Bri touches on how AJAC’s apprenticeship program…

Read More

February 26, 2019

AJAC Jumpstarts Automotive Youth Apprenticeship ProgramOver the last year, the Aerospace Joint Apprenticeship Committee has partnered with the Northwest Automotive Service Association and Independent Technicians Automotive Committee (ITAC) to council and guide their new General…

Read More