February 28, 2022

Rep. Kim Schrier Visits AJAC ApprenticesLast week, Congresswoman Dr. Kim Schrier contacted AJAC to learn more about our training programs in the 8th congressional district. She wanted an opportunity to meet apprentices who have excelled…

Read More

December 8, 2021

Workforce Training Remains Top Priority During Employer RoundtableNearly two years ago before the start of the pandemic, AJAC held its last in-person employer roundtable in Snohomish County. Since then, a dramatic shift in workforce development and skill…

Read More

October 7, 2021

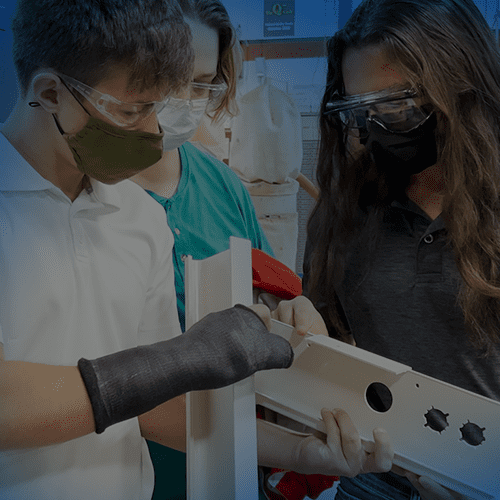

MFG Day 21 with Pexco AerospaceLaunched annually on the first Friday in October with events that continue throughout the month, MFG Day helps show the reality of modern manufacturing careers by encouraging thousands of…

Read More

August 23, 2021

Coffee Chats: Leveraging Apprenticeships to Strengthen Your WorkforceEconomic Alliance Snohomish County offers regular webinar’s through their Coffee Chat’s series. The topic on August 17th was Leveraging Apprenticeships to Strengthen Your Workforce. Participants included Angie Sievers, Snohomish STEM;…

Read More

July 6, 2021

AJAC Celebrates 129 Graduates from the Class of 2020 & 2021On June 22nd, AJAC held its first virtual apprenticeship graduation ceremony for the Class of 2020 and 2021—ushering in 129 graduates across six different apprenticeship occupations. These 129 graduates represented…

Read More

October 8, 2019

MFG Day (Manufacturing Day) 2019 | AJAC & Machinists Inc.Take a tour of Machinist Inc in Seattle, Washington as the Aerospace Joint Apprenticeship Committee (AJAC) and Hazen High School (Renton School District) celebrate National Manufacturing Day (MFG Day) 2019.…

Read More

July 11, 2019

2019 Washington Youth Apprenticeship Signing DayOn June 28, 2019, nearly 100 newly registered Youth Apprentices from across Washington State celebrated the beginning of their apprenticeship at the ShoWare Center in Kent, Washington. Signing Day brought…

Read More

October 9, 2018

Manufacturing Day Is More Than Inspiring, It’s FamilyFamily based. Good pay. Good benefits. Those were the three takeaways from students who toured Buyken Metal Products last Thursday as part of a nationwide celebration of manufacturing. Manufacturing Day—occurring…

Read More

July 3, 2018

2018 Youth Apprenticeship Signing Day CeremonyOn June 27, 2018, 67 newly registered Youth Apprentices signed their letter of agreement signifying a commitment to work in the aerospace and advanced manufacturing industries through the Aerospace Joint…

Read More

June 29, 2018

AJAC Celebrates 10th Anniversary with 72 Apprentice Graduates at The Museum of FlightSEATTLE, WA – On Friday, June 22nd, Washington State became home to 72 new aerospace and advanced manufacturing journeymen and women apprentices. The Aerospace Joint Apprenticeship Committee (AJAC) recognized the…

Read More

February 1, 2018

Focus Shifts to Broadening Youth Apprenticeships During 2018 Governor’s Youth Apprenticeship SummitApprenticeships are not an alternative to higher education. It is higher education. This sentiment rang loud and true during the 2018 Governor’s Youth Apprenticeship Summit, which in its second year,…

Read More

January 10, 2018

Governor Inslee Talks Youth Apprenticeship During ‘State of the State’ AddressGovernor Inslee delivered his annual State of the State Address to the Washington State Senate and the State House of Representatives on January 9, 2018. During his speech, Governor Inslee…

Read More

December 13, 2017

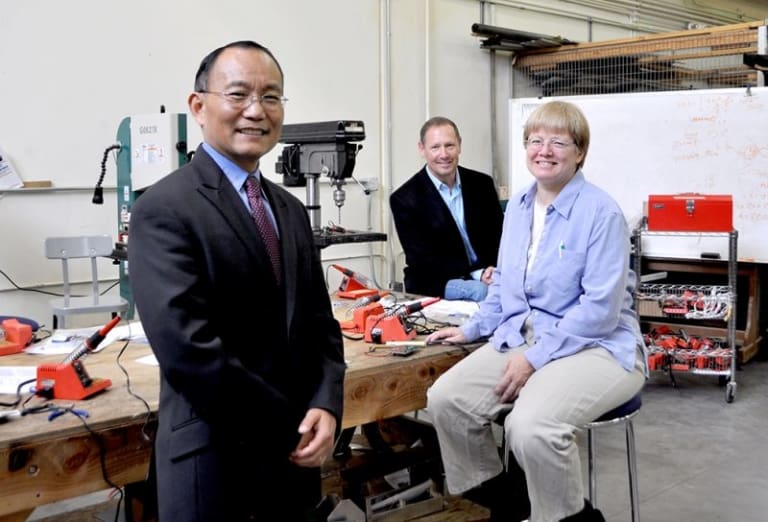

New Advanced Manufacturing Training Center Opens in Kent, WashingtonKent, Washington has a new home for advanced manufacturing. The Advanced Manufacturing Prep (AMP) Training Center was unveiled during a grand opening on December 6th in partnership with the City…

Read More

November 29, 2017

Gensco MFG Day 2017 (Video)On October 6, 2017, students from the Tacoma Public Schools (TPS) toured Gensco, Inc. as part of Manufacturing Day. Manufacturing Day is a celebration of modern manufacturing meant to inspire…

Read More

October 12, 2017

Manufacturing Day 2017: Opening Doors for the Next GenerationWhat does it mean to work in manufacturing? For some, they see it as an industry booming with innovative ideas and state-of-the-art technology. For others, they see engineers and machinists…

Read More

July 10, 2017

AJAC Celebrates the Class of 2017To become a journey-level worker signifies a changing of the guard – an ideology that mastery occurs on the job – not solely in the classroom. For AJAC’s 49 apprentice…

Read More

June 29, 2017

Manufacturing is STEM: Providing Career Connected LearningIn partnership with the Office of the Governor, the Workforce Board, WSU Extension, and the Office of the Superintendent of Public Instruction, Washington STEM traveled across the state to explore…

Read More

May 3, 2017

Yakima Ushers In First Youth ApprenticesYakima’s West Valley High School was given the baton last week to launch their first AJAC Youth Apprenticeship program. High school juniors Trevor Mackey, Osborne Rogers, and Bradley Ethier individually…

Read More

April 17, 2017

AJAC to Participate in Grays Harbor Career Pathway DayOn Monday, April 24, Grays Harbor Youth Works, Greater Grays Harbor, Inc., Aerospace Joint Apprenticeship Committee, and Grays Harbor College worked together to provide North Beach and Lake Quinault High…

Read More

April 10, 2017

Tacoma Celebrates First High School Apprentices During National Signing DayAll eyes were on Pacific Machine last week as the city of Tacoma ushered in a new era of career-connected learning. The decade-old mindset of ‘every student should attend a…

Read More

February 16, 2017

PNAA Selects AJAC for “Inspire Award”AJAC was honored to receive PNAA’s “Inspire” award during the annual Aerospace Conference in Lynnwood, Washington. AJAC’s Executive Director, Lynn Strickland accepted the award during the Aerospace Excellence Awards Banquet.…

Read More

February 15, 2017

AJAC Wins ‘Small Business of the Year’ AwardAJAC’s Exective Director, Lynn Strickland alongside Chamber CEO Andrea Reay On Friday, February 10th, AJAC was selected for the Seattle Southside Chamber of Commerce “Small Business of the Year” Award during…

Read More

January 26, 2017

KBTC-TV to Feature AJAC and Youth ApprenticeshipFrom left to right: Jody Robbins (L&I), Ron Langrel (Bates Technical College), Lynn Strickland (AJAC), John Altman (Governor’s Office) and Tom Layson (KBTC) The Aerospace Joint Apprenticeship Committee (AJAC) was…

Read More

November 4, 2016

Washington State to Launch First-Ever Youth Apprenticeship Program For High-Demand Industries(From left to right) Governor Jay Inslee, Lynn Strickland and Jesse Milbrath Over the last two years, the Aerospace Joint Apprenticeship Committee, Washington State Department of Labor and Industries, the…

Read More

October 7, 2016

Manufacturing Day Opens Doors for The Next GenerationThe Aerospace Joint Apprenticeship Committee partnered with Training Agent Buyken Metal Products for the third annual Manufacturing Day in Kent, Washington. Over 40 students from Kentridge High School and Kent…

Read More

September 16, 2016

Manufacturing Needs Women – So Let’s Train ThemThe Aerospace Joint Apprenticeship Committee, in partnership with the YWCA and South Seattle College hosted the first-ever Women in Manufacturing Symposium at South Seattle College – Georgetown Campus, highlighting…

Read More

August 29, 2016

Women in Manufacturing SymposiumJoin us for this forum and networking event introducing women to career and training opportunities in the exciting and dynamic field of advanced manufacturing. Hear from a panel of women…

Read More

August 29, 2016

Senator Patty Murray Visits Manufacturing AcademySenator Patty Murray stopped by the Seattle Manufacturing Academy program on August 9th to discuss how the Workforce Innovation and Opportunity Act (WIOA) has helped undeserved and disadvantaged individuals to…

Read More

August 29, 2016

Apprenticeships Can Change Lives, AJAC Grad SaysAJAC Machinist Graduate, Irwin Downes shaking hands with IAM 751 Organizer, Jesse Cote TUKWILA — Apprenticeships have the power to change lives. That’s the message graduates of the Aerospace Joint…

Read More