July 6, 2021

AJAC Celebrates 129 Graduates from the Class of 2020 & 2021On June 22nd, AJAC held its first virtual apprenticeship graduation ceremony for the Class of 2020 and 2021—ushering in 129 graduates across six different apprenticeship occupations. These 129 graduates represented…

Read More

June 19, 2020

Congratulations to the AJAC Class of 2020AJAC’s annual graduation ceremony at the Museum of Flight was postponed this year due to the COVID-19 global pandemic. Although we will celebrate all of our graduates during the 2021…

Read More

June 18, 2019

AJAC Graduates 79 Apprentices from 48 CompaniesOn June 14, 2019, the Aerospace Joint Apprenticeship Committee graduated 79 registered apprentices representing 48 companies from across Washington State. The apprentices were joined by their family, friends, and colleagues…

Read More

June 6, 2019

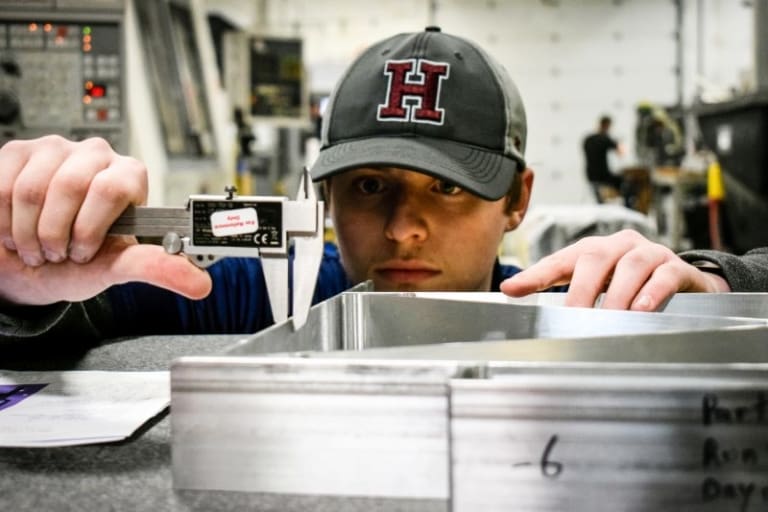

An Ordinary Teenager in an Extraordinary ApprenticeshipIt’s six in the morning at Tool Gauge, a Tacoma, Washington manufacturer that creates complex, high-quality plastic and metal parts and assemblies for the global aerospace industry. In walks a…

Read More

June 29, 2018

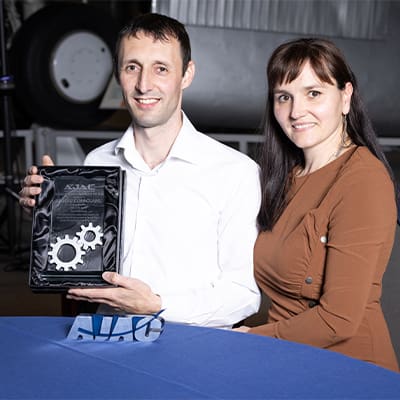

AJAC Celebrates 10th Anniversary with 72 Apprentice Graduates at The Museum of FlightSEATTLE, WA – On Friday, June 22nd, Washington State became home to 72 new aerospace and advanced manufacturing journeymen and women apprentices. The Aerospace Joint Apprenticeship Committee (AJAC) recognized the…

Read More

May 7, 2018

One Year In, AJAC Youth Apprentices Set To Graduate This JuneSeth Hamilton was nearing his 17th birthday and knew he wasn’t going to college. His after-high-school plans did not involve a four-year institution. Rising student loans and lack of finances…

Read More

July 10, 2017

AJAC Celebrates the Class of 2017To become a journey-level worker signifies a changing of the guard – an ideology that mastery occurs on the job – not solely in the classroom. For AJAC’s 49 apprentice…

Read More

August 29, 2016

Apprenticeships Can Change Lives, AJAC Grad SaysAJAC Machinist Graduate, Irwin Downes shaking hands with IAM 751 Organizer, Jesse Cote TUKWILA — Apprenticeships have the power to change lives. That’s the message graduates of the Aerospace Joint…

Read More