*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location. Source: ONET.

What is a Logistics Specialist?

Logistics Specialists are responsible for managing all supply functions, procure, receive, stow, issue, and inventory material.

In addition, logistics specialists perform inspection and audit of all supply areas, maintain financial records and reports, take corrective action on financial discrepancies, and make budget-related recommendations.

Logistics Specialists:

- Maintain supply management computer systems data,

- Generate required reports, and

- Maintain supply system integrity.

What are the Benefits of Becoming a Logistics Specialist?

A Logistics Specialist is an apprenticeship occupation that develops foundational skills for aspiring leaders or supervisors in logistics and warehouse management.

Upon completion of AJAC’s Logistics Specialist apprenticeship, you can move onto more advanced occupations such as operations specialist or industrial maintenance.

As a Logistics Specialist, you will enjoy a long-term career with a good salary, job advancement opportunities, and the chance to work with your hands and cutting-edge technology.

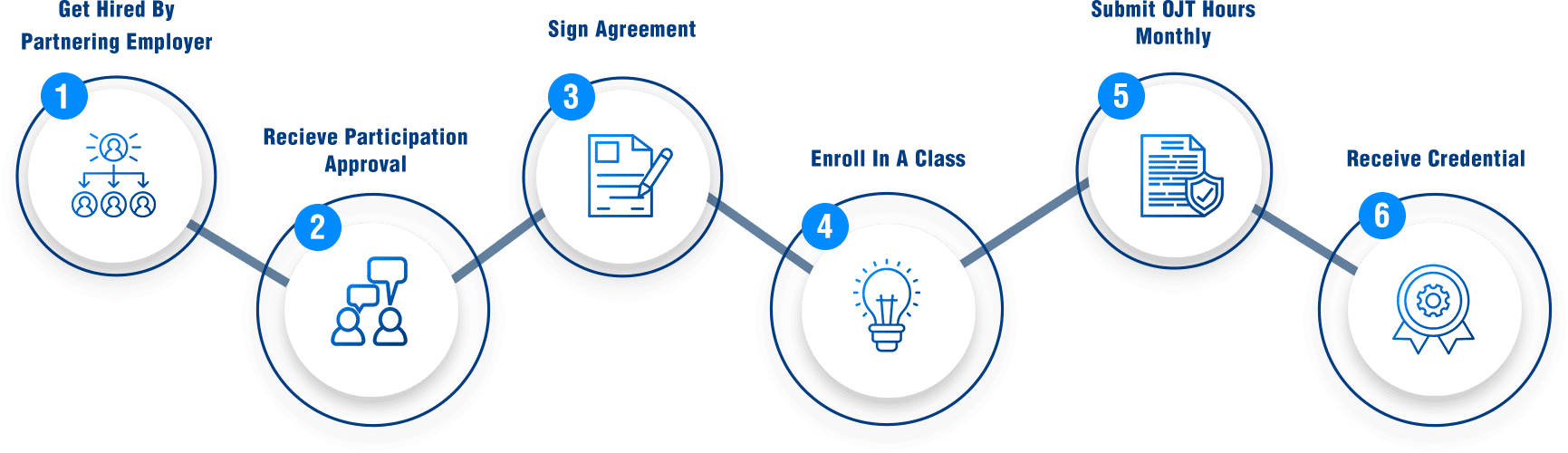

Step to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Get Hired by a Participating Employer AJAC Partners With

Receive Participation Approval from Your Employer

Sign an Apprenticeship Agreement with AJAC

Enroll in AJAC’s Apprenticeship Classes Each Quarter

Log and Submit Your OJT Hours Monthly

Receive a Nationally-Recognized Journey-Level Certification from L&I

How Much Can I Earn?

Where Will I Work?

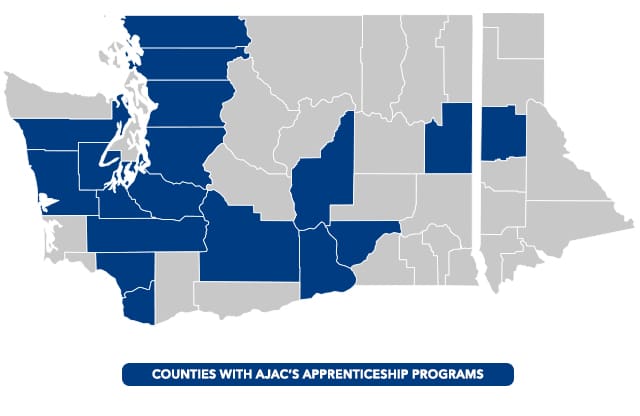

AJAC has partnered with 300+ advanced manufacturers to provide supervised, structured, paid on-the-job training.

AJAC apprentices can only work for companies that agree to hire them and place them into the program.

Each company has their own methodology for who they select as an apprentice.

Where Are Classes Held?

Classes are held one night a week, typically on a Tuesday, Wednesday, or Thursday from 5:00 pm to 9:00 pm.

AJAC’s apprenticeships classes are structured for both online learning or in-person learning. Depending on the specific class you are taking, you may be required to complete it online or in-person.

In-person classes are held either a local community/technical college, high school, or skills center.

Apprenticeship Classes

Logistics Specialist apprentices take five college-level classes. Each class consists of 50 hours of lecture and/or practical application. Upon completion of each class, apprentices will receive 5 college credits.

As a registered apprentice, you automatically receive 50% reduced tuition. Over half of AJAC’s partnering employers elect to pay for their apprentice’s tuition, making the entire apprenticeship free-of-cost.

Currently, each class costs $300 out-of-pocket.

In this course, students will explore concepts related to various functions within operations and supply chain management. They will develop an understanding of complex processes to be followed to bring a finished product to life for consumers. Students will explain how new demands, advancing technology, changing preferences, and unforeseen circumstances force companies to adapt to survive and create new products. Students will also gain foundational knowledge, including logistics and warehouse management principals, in a non-technical way to help them understand their work.

Apprentices are introduced to basic communication concepts relating to the workplace. Concepts include theory and skills practice related to interpersonal, intercultural, and production team communications, technical writing and business communications, phone and email etiquette, and conflict management. Students will create a professional portfolio that includes a resume, examples of skills, accomplishments, and samples of work.

In this course, students will be able to relate LEAN Six Sigma concepts to production objectives. They will identify waste within the value stream and demonstrate the ability to effectively analyze and present data to co-workers and stakeholders. They will define and apply team leadership tools to aid in process improvement. Students will collect and process customer or internal stakeholder input/requirements and identify key metrics for measuring success. Students will define the DMAIC process and effectively use tools and concepts associated with each phase of the DMAIC process. Finally, they’ll employ Lean Six Sigma skills in process improvement projects.

In this course, students will describe types of inventory and develop an understanding of the financial accounting of inventory. They will also learn where to locate inventory and ways to control its location. Students will explore the uses, advantages, and disadvantages of automated inventory systems such as bar codes and RFID. They will describe ways to manage inventory and explain causes of inventory system failures as well as ways to fix the problems. Students will also explore some of the basic risks of supply chain management as well as solutions to some common problems. Finally, students will explore the importance of warehouse safety by focusing on injury prevention and reporting, forklift safety, and ergonomics. 8 hours of safety in this course.

Enterprise Resource Planning (ERP) refers to a method or type of software that organizations use to manage day-to-day activities. In this course, students will explore ways that ERP is used to efficiently manage demand and procurement. They will explain how ERP is used to quantify resource use, and better plan production jobs and product delivery. Students will use ERP to create invoices to send directly to customers or create and transmit import and export documentation required for cross-border shipments. Students will also identify how ERP processes enhance collaboration between businesses and vendors, helping to reduce bottlenecks. Students will explore how ERP use can help target inefficiencies in resource use and improve business outcomes. Finally, students will explain how ERP can help organizations adapt during business downturns. 3.5 hours of safety in this course.

On-the-Job Training Competencies

The table below is a schedule of tasks and hours designed as a guide. The 3,000 hours will be completed over the course of the apprenticeship. The apprentice shall be instructed and trained in all operations and methods customarily used on the various machines. Each company will adhere to the schedule as closely as facilities will permit in order to provide the apprentice with well-rounded experience and practice on all relevant equipment and processes in the shop.

| OJT Competency | Approx. OJT Hours |

|---|---|

| Inventory & Production Management | 1,000 |

| Distribution & Logistics Operations | 800 |

| Storage & Warehousing Operations | 800 |

| LEAN/6Sigma Projects | 200 |

| Internal & External Customer Service | 200 |

| TOTAL HOURS | 3,000 |

Launch Your Career Today!

Submit your information using the link below. After we receive your information, an AJAC representative will contact you for next steps. Please note, this is not an official application to become an apprentice. After a partnering employers agrees to enroll you in the program, you will officially apply and enroll at that time.