Youth Apprenticeship transforms how education systems prepare young people to enter careers and launch into adulthood through mutually beneficial partnerships across schools, industry and communities.

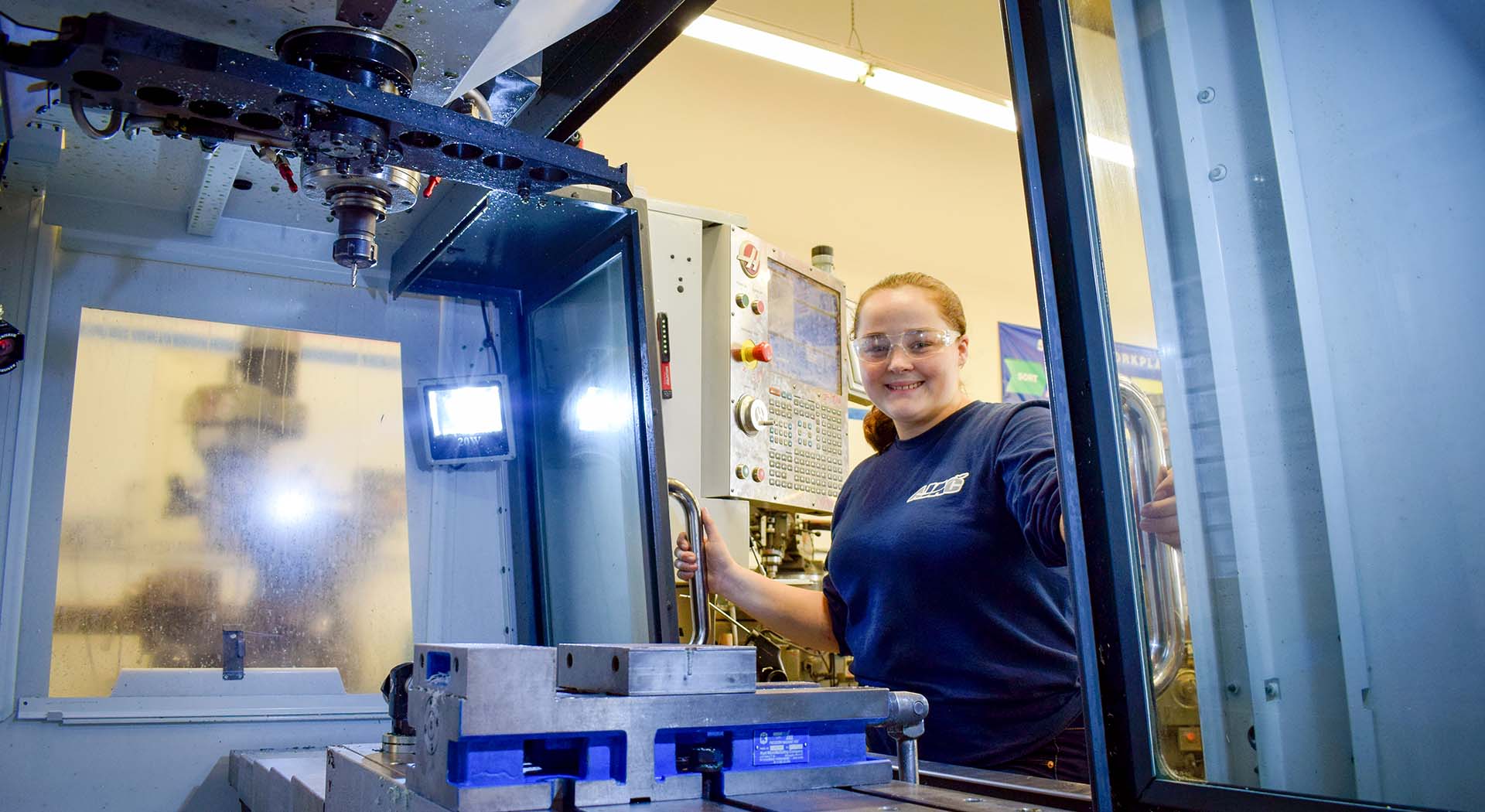

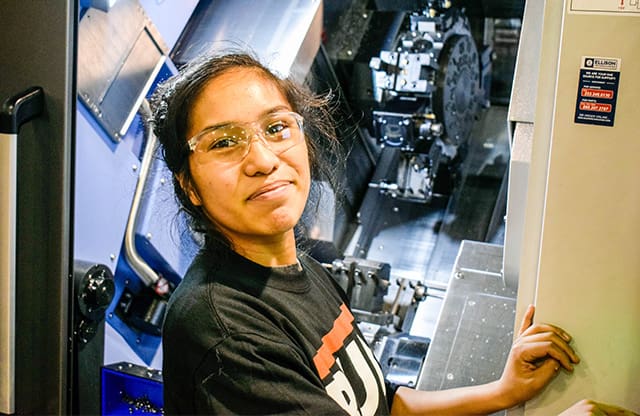

AJAC’s Production Technician (Youth) and Automation Technician (Youth) Apprenticeships are 2,000 hour programs designed for high school juniors and seniors to develop career-ready skills in the advanced manufacturing industries.

These apprenticeship programs create opportunities for youth apprentices to finish high school, start their post-secondary education at little-to-no cost, complete paid work experience alongside a mentor, and start along a path that broadens their options for the future.