*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location. Source: Washington State Employment Security Department 2021 Occupational Employment and Wage Estimates.

What is an Industrial Manufacturing Technician?

The Industrial Manufacturing Technician’s (IMT) operates production equipment as well as assembles applicable components.

Manufacturing technicians must closely follow guidelines, blueprints, and/or diagrams of the products being manufactured; this is important to ensure that all the necessary product specifications are met and comply with the company’s standards.

Industrial Manufacturing Technicians:

- Set-up, operate, monitor, and control production equipment

- Improve manufacturing processes and schedule to meet customer requirements

- Understand manufacturing as a business system that integrates multiple disciplines, processes, and stakeholders

- Efficiently and safely manage raw materials/consumables

What are the Benefits of Becoming an Industrial Manufacturing Technician?

An Industrial Manufacturing Technician is an entry-level apprenticeship occupation that develops foundational manufacturing skills for aspiring manufacturers.

Upon completion of an Industrial Manufacturing Technician apprenticeship, you can move onto more advanced occupations such as machining or industrial maintenance.

As an Industrial Manufacturing Technician, you will enjoy a long-term career with a good salary, job advancement opportunities, and the chance to work with your hands and cutting-edge technology.

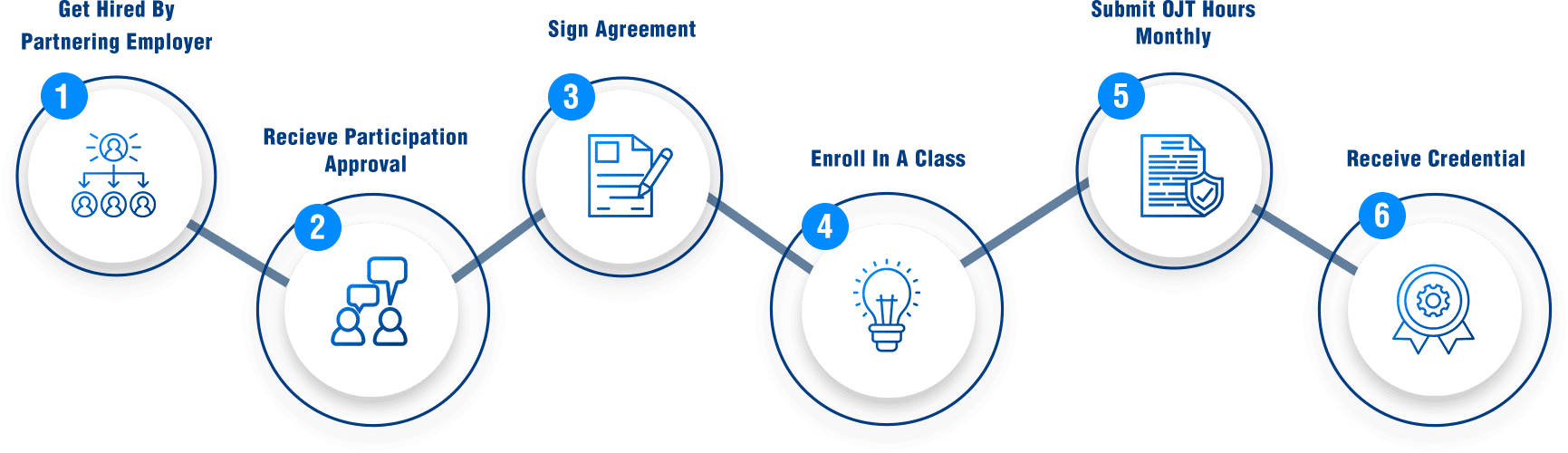

Step to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Get Hired by a Participating Employer AJAC Partners With

Receive Participation Approval from Your Employer

Sign an Apprenticeship Agreement with AJAC

Enroll in AJAC’s Apprenticeship Classes Each Quarter

Log and Submit Your OJT Hours Monthly

Receive a Nationally-Recognized Journey-Level Certification from L&I

How Much Can I Earn?

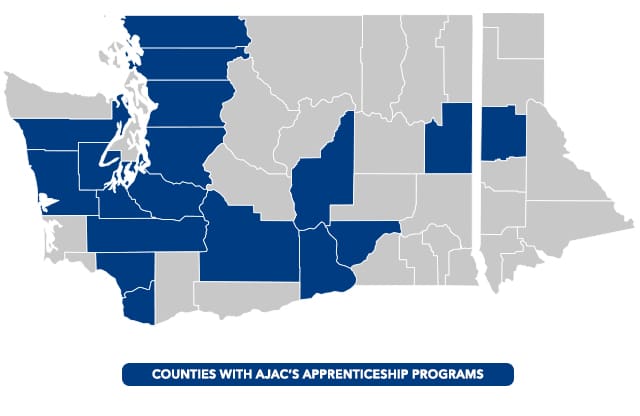

Where Will I Work?

AJAC has partnered with 300+ advanced manufacturers to provide supervised, structured, paid on-the-job training.

AJAC apprentices can only work for companies that agree to hire them and place them into the program.

Each company has their own methodology for who they select as an apprentice.

Where Are Classes Held?

Classes are held one night a week, typically on a Tuesday, Wednesday, or Thursday from 5:00 pm to 9:00 pm.

AJAC’s apprenticeships classes are structured for both online learning or in-person learning. Depending on the specific class you are taking, you may be required to complete it online or in-person.

In-person classes are held either a local community/technical college, high school, or skills center.

Apprenticeship Classes

Industrial Manufacturing Technician apprentices take six college-level classes. Each class consists of 50 hours of lecture and/or practical application. Upon completion of each class, apprentices will receive 5 college credits.

As a registered apprentice, you automatically receive 50% reduced tuition. Over half of AJAC’s partnering employers elect to pay for their apprentice’s tuition, making the entire apprenticeship free-of-cost.

Currently, each class costs $300 out-of-pocket.

Basic shop safety, PPE, safe operator performance, identifying unsafe conditions & corrective actions, enhancing workplace practices, OSHA-10, CPR/First Aid, environmental assessments, emergency terms & drills.

Quality & continuous improvement practices, introduce QA, blueprint reading, interpreting manufacturing documents, precision measurement, basic tools/equipment use and knowledge.

Production for customers’ needs, required resources, lean manufacturing, communicate production, job assignments & work flow, set-up & machine operations, problem solving, shipping & receiving.

Preventive and routine maintenance awareness, applied principles of machine control and automation concepts, welding, basic electricity, fluid power systems, understanding applications for lubricants, coolants, bearings, couplings, belt drives and chain drives.

Review of basic arithmetic, basic algebra application, based on geometry, right angle trigonometry, oblique angle trigonometry, and right angles.

Concepts related to the workplace including writing a technical memo, explaining technical processes, giving clear instruction, mediation/negotiation, conflict resolution, and group facilitation.

On-the-Job Training Competencies

The table below is a schedule of tasks and hours designed as a guide. The 3,000 hours will be completed over the course of the apprenticeship. The apprentice shall be instructed and trained in all operations and methods customarily used on the various machines. Each company will adhere to the schedule as closely as facilities will permit in order to provide the apprentice with well-rounded experience and practice on all relevant equipment and processes in the shop.

| OJT Competency | Approx. OJT Hours |

|---|---|

| Set-Up Production Equipment | 800 |

| Operate Production Equipment | 1,000 |

| Quality Assurance, Inspection & Measurement | 600 |

| Interpret Technical Information | 200 |

| Routine Machine Maintenance | 300 |

| Inventory Materials | 100 |

| TOTAL HOURS | 3,000 |

Launch Your Career Today!

Submit your information using the link below. After we receive your information, an AJAC representative will contact you for next steps. Please note, this is not an official application to become an apprentice. After a partnering employers agrees to enroll you in the program, you will officially apply and enroll at that time.