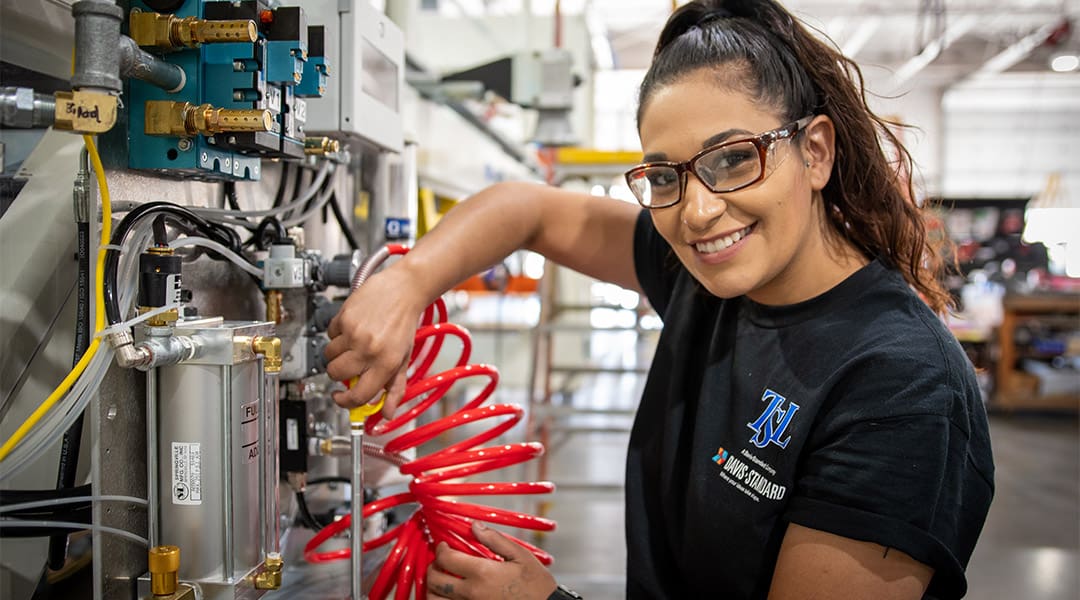

Thermoforming Systems (TSL), a Davis-Standard Company, began their partnership with AJAC in 2021 in an effort to skill-up their employees at their Union Gap facility. AJAC worked closely with management to customize the Industrial Manufacturing Technician (IMT) program to ensure the competencies learned on the job and college-level classes aligned with their work developing thermoforming equipment.

Over the last two years, nearly 50 TSL employees have enrolled in AJAC apprenticeship programs. Most of these workers engaged in AJAC’s 18-month IMT apprenticeship program, which focuses on operating production equipment, reading blueprints, and assembling applicable components.

What makes TSL’s partnership with AJAC unique is their adoption of the cohort model. Often times, AJAC’s partnering employers enroll a few apprentices at a time. These apprentices attend their classes with other apprentices from neighboring companies and communities. AJAC’s cohort model gives employers the chance to have a large group of their own employees learn at the same pace, work with each other to identify challenges they encounter on the shop floor, and collaborate on process improvements in a structured classroom environment at their own facility.

More recently, the cohort model has taken off across Washington State. Chemi-Con Materials in Moses Lake enrolled six AJAC apprentices in 2021 to help grow their maintenance department. Manufacturers across the board continue to see a trend developing–traditional methods of growing your workforce are changing and adopting internal training programs such as apprenticeship can be key to retaining the talent companies hire.

About TSL:

Thermoforming Systems (“TSL”) designs, manufactures and markets leading-edge thermoforming equipment to the food packaging industry. TSL’s thermoformers are largely used in food and beverage end markets throughout North America, with millions of cups, plates, lids, and trays produced on TSL’s technology every year.