October 4, 2021

Berry Global Youth Internship ProgramBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

July 19, 2021

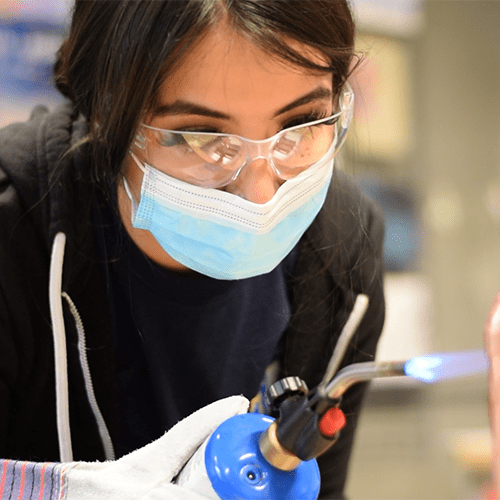

AJAC Trains Opportunity Youth for Manufacturing CareersBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

March 5, 2021

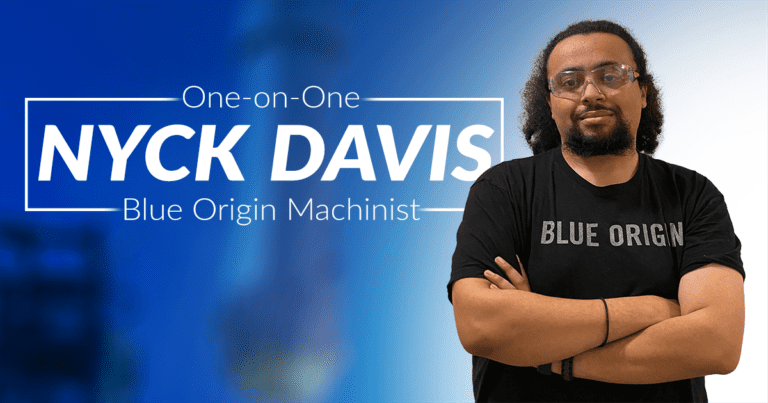

Blue Origin Apprentice Talks Manufacturing Academy & ApprenticeshipNyck Davis spent his afternoons measuring objects around his house. The COVID-19 pandemic forced Nyck to reimagine himself, not as a former automotive technician at Mercedes Benz, but as a…

Read More

November 30, 2020

She Was Ready for a Fresh Start, Now She’s Got a Fresh CareerShe was ready for a fresh start, now she’s got a fresh career | Renton Reporter Connect to training – and employers hungry for new talent – in advanced manufacturing.…

Read More

November 3, 2020

Juvenile Rehabilitation Students Harvest Opportunity to Give BackIt’s shortly after 8 o’clock in the morning on a farm outside of Tacoma, Washington. Summer has ended and the mornings have become brisk with a layer of fog blanketing…

Read More

February 26, 2020

Our Mission. Their Story.Meet LaDante Weems—a formerly incarcerated youth and now graduate of the AJAC Juvenile Rehabilitation Manufacturing Academy program—tells his story on becoming a full-time employee at Tech Marine. We at AJAC…

Read More

January 31, 2020

AJAC Provides Apprenticeship Preparation Program For High School StudentsAJAC is launching a new Manufacturing Academy program in Federal Way through a partnership with the Federal Way Boys & Girls Club, Truman High School and a grant from Aspen…

Read More

September 23, 2019

Manufacturing Academy Students Develop Financial Stability Through New Wells Fargo PartnershipThe Wells Fargo Foundation, established in the U.S. as a registered 501(c)(3) charitable organization in 1980, is the company’s primary philanthropic funding arm. In 2018, the foundation donated nearly half…

Read More

August 22, 2019

The Boy WonderWhen you walk into AJAC’s Manufacturing Academy at South Seattle College-Georgetown Campus the first thing you’ll notice is the intimidating computer numerical controlled (CNC) and manual machines scattered around the…

Read More