How did the Manufacturing Academy set you up for a new career in manufacturing?

MA prepared me for working in manufacturing in many ways, but I’d say reading blueprints and taking precise measurements have been the most prevalent in my day-to-day at work.

Where would you be today had you not enrolled in the Manufacturing Academy?

Probably still bartending, which isn’t bad work, but I was ready for something with more growth and that would allow me to continuously learn and improve.

How did the Manufacturing Academy get you excited about working in the industry?

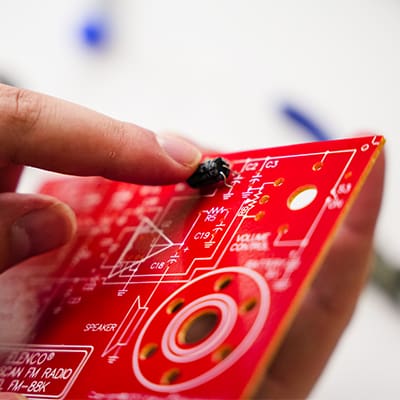

I was shown and told about a variety of careers and types of work in the manufacturing field which allowed me to see what I might prefer doing, and see the awesome hands-on work that I could do. Anytime I saw something exciting in class, I would look it up online and see careers following that path.

Was there a point during your time as a Manufacturing Academy student where you said to yourself, “This is something I want to do as a career?”

Honestly, we did an exercise where we had to build a Lego structure and then draw a blueprint based on it. I remember intentionally building a bizarre structure out of my Lego blocks, with parts and pieces jutting off in interesting ways, because I wanted to challenge myself with a more difficult print drawing. That excitement was definitely a piece of my “ah-ha” moment, but more so felt like validation I was on the right path because I did come into MA with the intention of starting a career and finding an apprenticeship opportunity.

What would you say to other women who have not considered working in manufacturing yet? What would tell them that would encourage them to follow in your footsteps?

There are so many different paths and focuses in manufacturing, from aerospace plastics production like I’m doing to working with the hops that go into beer to the everyday things like the keyboard I’m typing on, and in all those various avenues of manufacturing there are so many positions and opportunities. I chose something more hands-on, that keeps me active and using my muscles while also challenging my mind and encouraging me to problem solve, but there are paths that differ from mine that might challenge you in things you’re passionate about. If you’re excited about it, pursue it!