Nyck Davis spent his afternoons measuring objects around his house. The COVID-19 pandemic forced Nyck to reimagine himself, not as a former automotive technician at Mercedes Benz, but as a future employee of Blue Origin.

Nyck’s fortune was waiting to be told. He heard about the Manufacturing Academy from a friend who recently graduated from AJAC’s pre-apprenticeship program. He encouraged him to apply since he needed a new direction—a new skillset—that could attract some of the top aerospace companies in the state.

“I knew you could always make some crazy things being a machinist. It blows my mind knowing how much work goes into machining. You have to study the blueprints, do all the math, figure out how to set-up the machine and what cutters to use,” Davis said.

The Manufacturing Academy provided Nyck with a creative outlet to hone his skills and understand how things are made from raw materials.

I keep saying it and I’ll never stop saying it, I will never have the job I have now without the AJAC program.

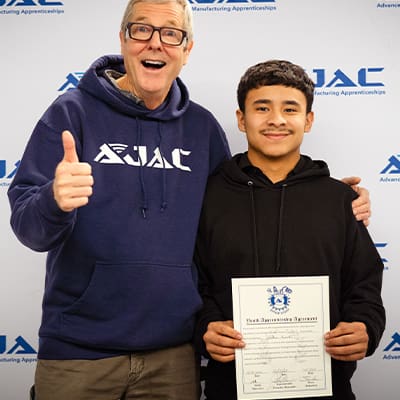

Troy Ironmonger, AJAC’s Manufacturing Academy instructor worked with Nyck and his peers to prepare them for a career in advanced manufacturing, “Nyck’s drive to become a machinist was evident from the first day. He was able to build on the skills he learned in his high school shop class, as an automotive technician, and apply those to our class,” Ironmonger said.

As the Manufacturing Academy program came to a close, Nyck began his employment search, looking for companies that could elevate his foundational machining knowledge.

His sights were set on one company—Blue Origin. “I applied to eight or nine different positions and eventually landed on apprentice machinist. Luckily, it was announced the last week of class that Blue Origin is now a sponsor of the AJAC program,” Davis said. “Timing wise, I got extremely lucky and I ended up landing the apprentice machinist job.”

Six weeks after becoming a full-time employee at Blue Origin, Nyck was ready to begin his career as an AJAC machinist apprentice. His first two quarters covered engineering drawings and shop algebra, two concepts Nyck became familiar with in the Manufacturing Academy. Now in his third quarter, Nyck is learning the theory behind precision machining, including manual machining, tolerances, speeds and feeds, and parts finishing.

Looking back on his journey from becoming unemployed, to landing his dream job, Nyck is humbled by those who gave their time to grow his craft, “I am super excited to be a part of this program. I keep saying it and I’ll never stop saying it, I will never have the job I have now without the AJAC program. If you’re thinking about getting into the AJAC apprenticeship, I would say do it! It’s completely worth it. If you have what you want to do in mind and you work hard to get there, you will not regret it!”

To learn more about AJAC’s Manufacturing Academy program, please visit: www.ManufacturingAcademy.org.