Grow your knowledge and skill sets in industrial maintenance — earn while you learn, gain 8,000 hours of hands-on training and a nationally-recognized credential.

Launch Your Career

Train for a Career in Industrial Maintenance

Industrial Maintenance Technicians are essential to keeping factories and manufacturing facilities running smoothly. They install, repair, and maintain machinery across industries like food processing, aerospace, maritime manufacturing, biomedical, defense, space, and packaging.

As an Industrial Maintenance Technician apprentice, you’ll gain hands-on experience troubleshooting equipment, performing preventive maintenance, and developing advanced mechanical and electrical skills.

| Program Length | 4-Years |

| On-the-Job Hours | 8,000 |

| College Classes | 12 |

| College Credits | 60 |

Hands-On Training That Builds Real Skills

Industrial Maintenance Technicians ensure machinery operates efficiently and safely. As an apprentice, you’ll learn to:

- Read technical manuals and blueprints to understand equipment and controls

- Disassemble machinery and equipment for maintenance and repair

- Perform tests and operate machinery to verify functionality

- Adjust and calibrate equipment to optimal specifications

- Apply knowledge of electrical, mechanical, and fluid power systems to solve real-world problems

Every manufacturing facility depends on skilled maintenance technicians — that’s your role.

Why Apprenticeship Makes Sense

Hands-On Training with Real Employers

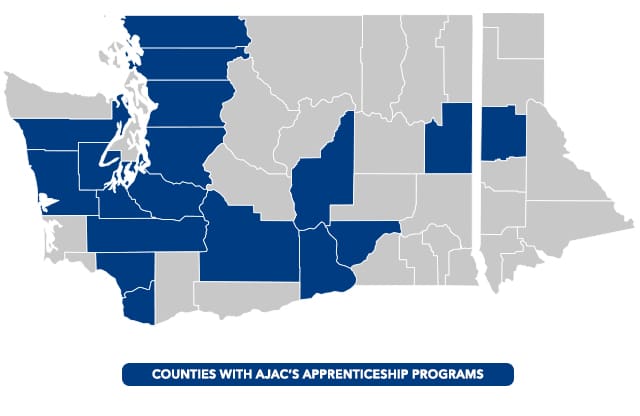

AJAC partners with 300+ advanced manufacturers in Washington and Idaho to provide supervised, structured, paid training.

Apprentices work only with employers that agree to hire and enroll them in the program. Each employer has its own selection process for apprentices.

Earn a Paycheck While You Learn

This advanced apprenticeship builds expertise in machinery operation, maintenance, and repair while providing real-world experience.

Career Benefits:

- Paid on-the-job training while you learn

- 50% reduced tuition (many employers cover full cost)

- 60+ college credits (12 classes × 5 credits each)

- Nationally recognized journey-level credential

- Career paths into Supervisor, Shift Lead, Maintenance Manager, or Operations Manager

*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location.

Apprenticeship Classes

Classes are held one evening per week (Tuesday–Thursday, 5–9 PM) and are available online or in person at local colleges, high schools, or skill centers. Tuition: $400 per class (50% reduced rate). Many employers pay the full cost.

Learn to read and interpret engineering drawings and schematics, as well as practice basic drafting. Drawings studied in this class will come both from the text and from industry, and will include machining, fabrication, assemblies, and fluid power systems (only for Automation/Maintenance program).

The apprentices will learn about the practical application and safe operation of lifting equipment commonly used in industrial maintenance such as forklifts, scissor lifts, and cranes.

Fundamental manual machining skills and knowledge to include topics such as job plans, drawings, tolerances, engineering specifications and use of manual tools.

Explore theory and practice for cutting processes such as oxyfuel cutting, plasma cutting, and ironworker operation. Apprentices will practice welding techniques using the following processes: GMAW (MIG welding), SMAW (stick welding), and OAW.

In this course, apprentices will learn about industrial electrical theory, components, and equipment necessary to troubleshoot electrical problems. Apprentices will begin by learning to interpret electrical symbols, diagrams, and terminology.

This course explores advancing technologies in manufacturing relevant to industrial maintenance, including computer numerical control (CNC) technology, automation, and programmable logic controllers (PLCs).

Apprentices will develop a working knowledge and practical application of mathematics as it relates to industrial maintenance. All basic math concepts will be covered, including adding, subtracting, multiplying and dividing fractions, ratio, proportion and percentages.

The apprentices will explore intermediate-level theory, application, and hands-on experience with precision machining practices for industrial maintenance.

Learn to maintain all of the elements of a mechanical system. Apprentices will begin by exploring mechanical fundamentals such energy, mechanical forces, and simple machines. Apprentices will learn to troubleshoot, assemble, and maintain couplings, gears, pulleys, chains, sprockets, and brakes.

Apprentices will explore the fundamentals of fluid power systems, including structures and components, operation, safety, as well as interpreting related standards, symbols, and diagrams. Hydraulic fluid types, properties, handling, and maintenance topics will be covered.

Comprehensive understanding of outside processes and the properties of materials that are governed by industry standards.

In this course, apprentices will design, build, and implement a mechatronics project that incorporates skills that have been studied and practiced throughout the industrial maintenance technician apprenticeship.

8,000 Hours of Hands-On Experience

Apprentices gain hands-on experience with structured tasks to ensure well-rounded expertise:

| OJT Competency | Approx. OJT Hours |

|---|---|

| Machine Operation | 1,000 |

| Inspection & Bench Work | 1,000 |

| Installation of Machinery & Equipment | 1,000 |

| Maintenance of Machinery & Equipment | 2,500 |

| Repair of Machinery & Equipment | 2,500 |

| TOTAL HOURS | 8,000 |

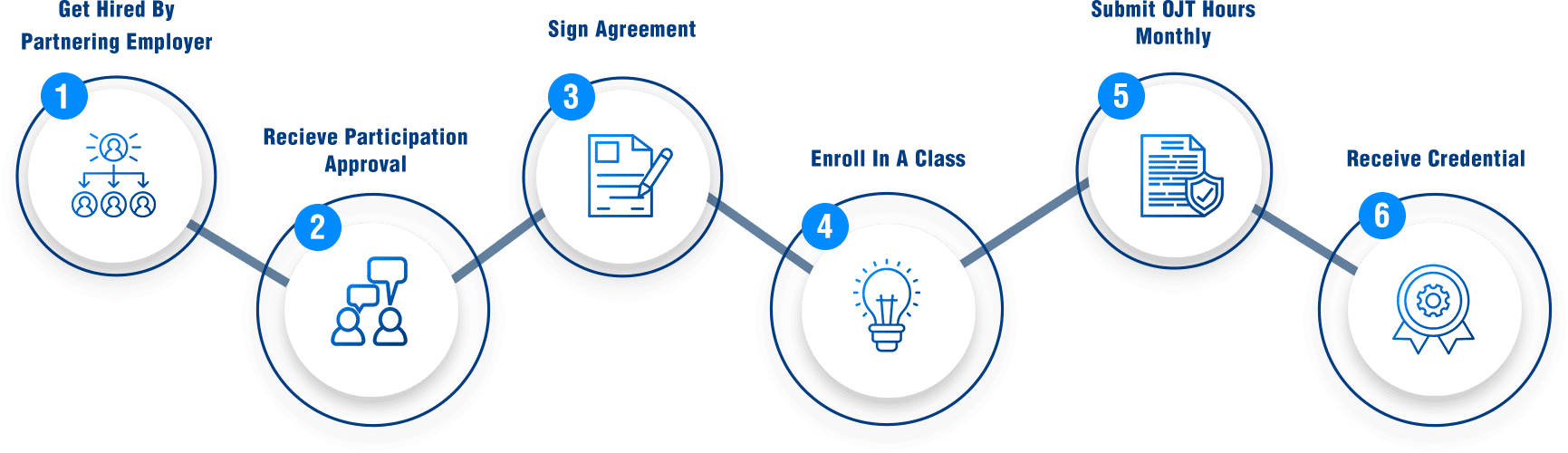

Step to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Find an Employer Partner: Apply to a company already partnered with AJAC — or, if your employer isn’t yet a partner, they can easily join the program. The process is simple and AJAC will guide them through every step.

Get Company Approval: Your supervisor signs off on apprenticeship participation.

Sign the Apprenticeship Agreement: AJAC visits your employer to finalize.

Start Classes: Enroll in your first college-level course.

Track Hours: Log on-the-job training through AJAC’s Apprentice Tracking System.

Graduate: Earn your Journey-Level Certificate and AJAC Certificate of Completion.

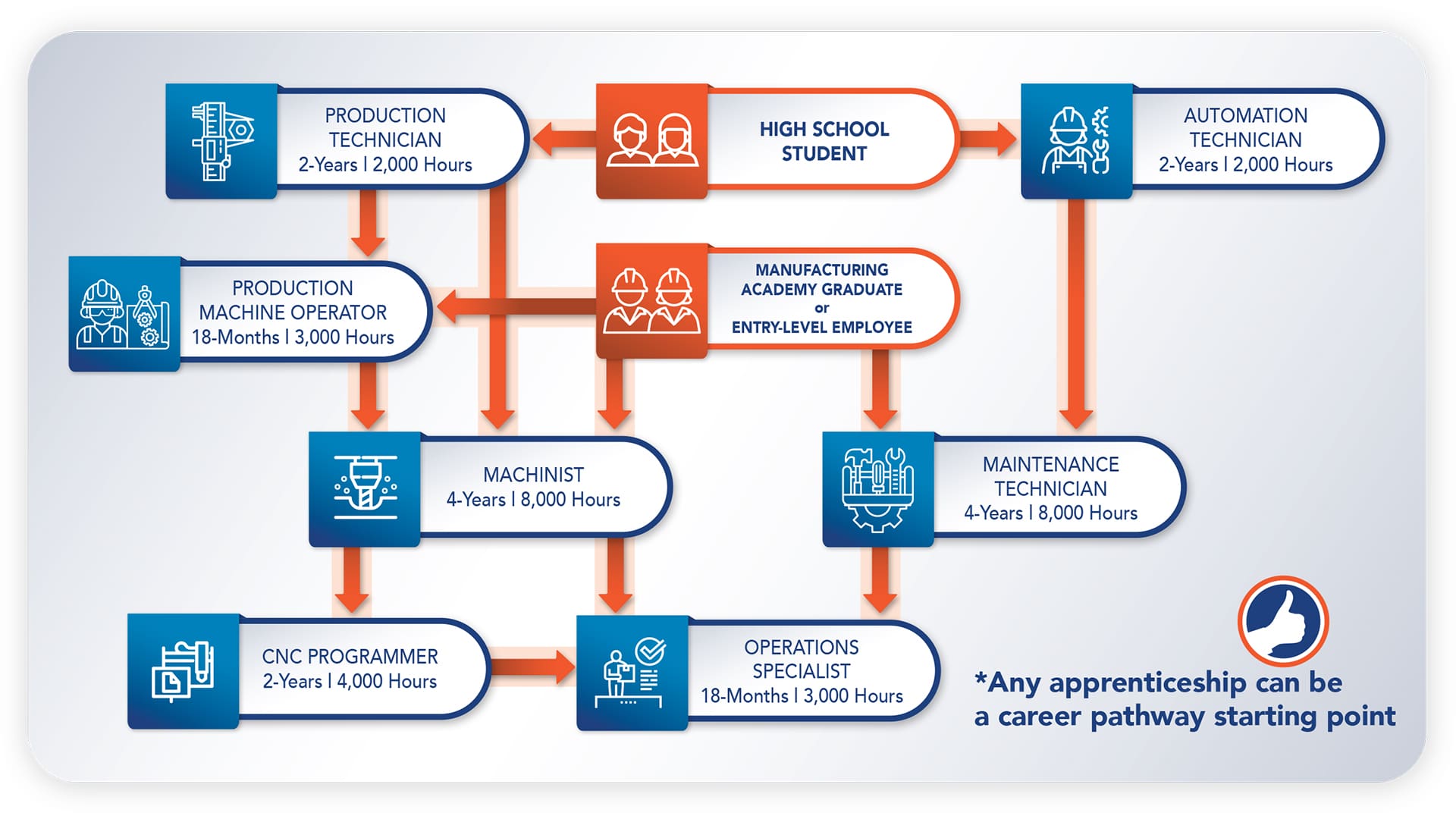

Start Small. Stack Big.

No matter where you begin—whether it’s running machines or maintaining equipment—AJAC’s Stackable Apprenticeships give you the power to keep climbing in your career pathway.

Start in an entry-level role and build your way into highly skilled, specialized, or even leadership positions—all without student debt. Each program builds on the last, helping you expand your skills, increase your earning potential, and take on new responsibilities—without putting your career on hold.

Launch Your Career Today!

Submit your information using the link below. After we receive your information, an AJAC representative will contact you for next steps. Please note, this is not an official application to become an apprentice. After a partnering employer agrees to enroll you in the program, you will officially apply and enroll at that time.