March 22, 2021

AJAC Apprentice Encourages More Women to Pursue ManufacturingAJAC Machinist apprentice, Mallory Martindale, was invited to speak on a panel regarding women in nontraditional occupations hosted by WANTO. Mallory is nearly complete with her four-year machining apprenticeship, and…

Read More

March 5, 2021

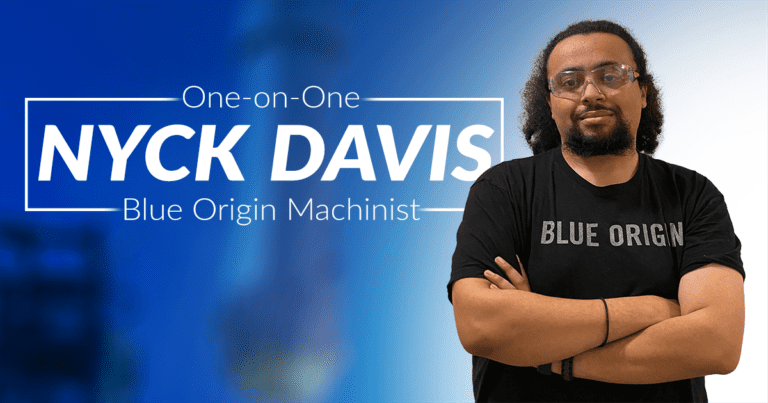

Blue Origin Apprentice Talks Manufacturing Academy & ApprenticeshipNyck Davis spent his afternoons measuring objects around his house. The COVID-19 pandemic forced Nyck to reimagine himself, not as a former automotive technician at Mercedes Benz, but as a…

Read More

January 21, 2021

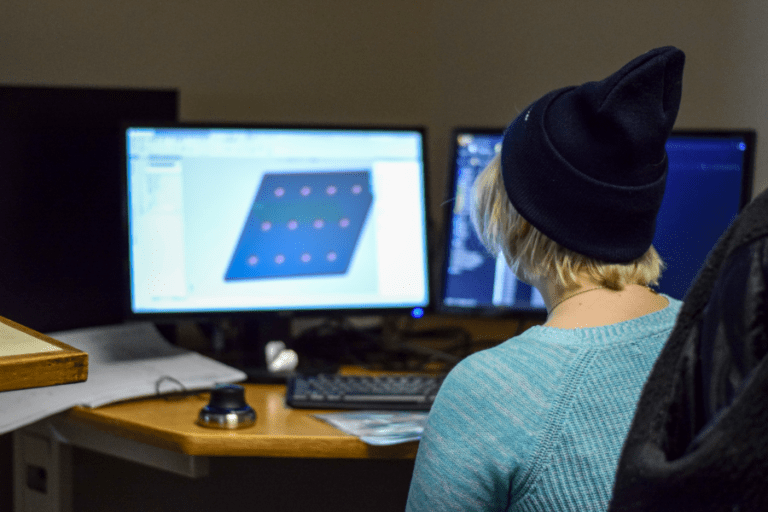

AJAC Launches New CNC Programmer ApprenticeshipThe Aerospace Joint Apprenticeship Committee (AJAC) is excited to offer a new CNC Programmer Apprenticeship this spring! This program combines on-the-job training (OJT) with evening classes one night a week. AJAC…

Read More

December 15, 2020

Why I Chose Manufacturing | Kailey HardingKailey Harding’s interest in manufacturing first peaked when she saw students making carbon fiber skateboards at the Pierce County Skills Center. As an avid longboarder, she was immediately drawn to…

Read More

November 23, 2020

Lift off! Take your career from the launch pad to the stratosphereLift off! Take your career from the launch pad to the stratosphere | Kent Reporter Aurelia Greene has completed all of the college-level classwork for her Aerospace Joint Apprenticeship Committee…

Read More

November 12, 2020

One-on-One with Evan Thomas, AJAC Machinist GraduateTo celebrate National Apprenticeship Week 2020, AJAC sat down with former machinist graduate, Evan Thomas, for a candid interview about his apprenticeship experience. Our 24-minute conversation covered a wide variety…

Read More

November 9, 2020

Advanced Manufacturing Apprenticeships Launch Out-of-This-World OpportunitiesAdvanced manufacturing apprenticeships launch out-of-this-world opportunities | HeraldNet.com Mallory Martindale’s apprenticeship with the Aerospace Joint Apprenticeship Committee is almost complete. She’s been working in manufacturing since she graduated high school,…

Read More

May 7, 2018

One Year In, AJAC Youth Apprentices Set To Graduate This JuneSeth Hamilton was nearing his 17th birthday and knew he wasn’t going to college. His after-high-school plans did not involve a four-year institution. Rising student loans and lack of finances…

Read More

January 8, 2018

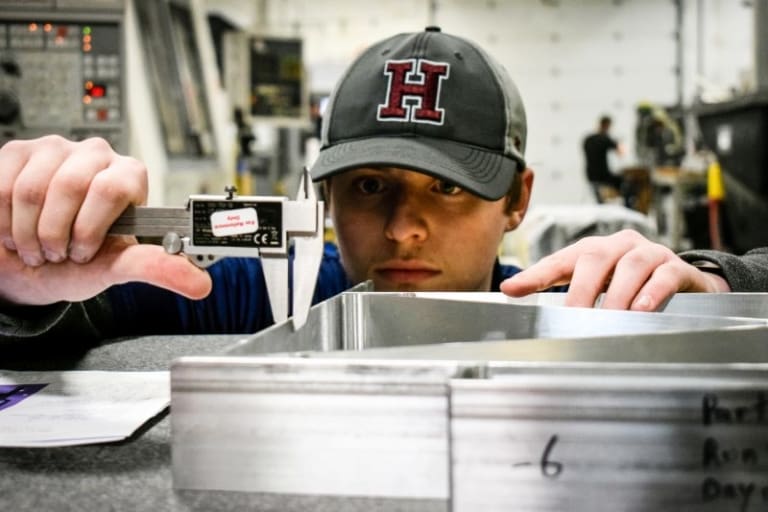

Machining Apprenticeship Provides Alternative Career PathwayTrevor Mohon, a first-year machinist apprentice at RTC Aerospace – Fife Division, discusses his decision to pursue machining after high school. Trevor explains how this industry has challenged him, the…

Read More

September 16, 2016

Manufacturing Needs Women – So Let’s Train ThemThe Aerospace Joint Apprenticeship Committee, in partnership with the YWCA and South Seattle College hosted the first-ever Women in Manufacturing Symposium at South Seattle College – Georgetown Campus, highlighting…

Read More

August 29, 2016

Disadvantaged Youth Learn Aerospace While in High School (Video)In 2012, the median age in manufacturing was nearly 45 years old, a number that is expected to rise continually over the next decade. An influx of young talent into…

Read More

August 29, 2016

Tommy – Boeing Tech, Pioneer IndustriesTommy grew up in a big family with three brothers and two sisters in Grays Harbor on Washington State’s coast. He was involved in school and sports as a young…

Read More

August 29, 2016

Inspiration in Machinist’s Training at Senior Aerospace AMT[vimeo src=167495188] The Victory Series | Episode 12 Featuring Matt Washburn of Senior Aerospace AMT from 4th Avenue Media on Vimeo. How a business leader is keeping manufacturing and machining…

Read More

August 29, 2016

Apprenticeships Can Change Lives, AJAC Grad SaysAJAC Machinist Graduate, Irwin Downes shaking hands with IAM 751 Organizer, Jesse Cote TUKWILA — Apprenticeships have the power to change lives. That’s the message graduates of the Aerospace Joint…

Read More