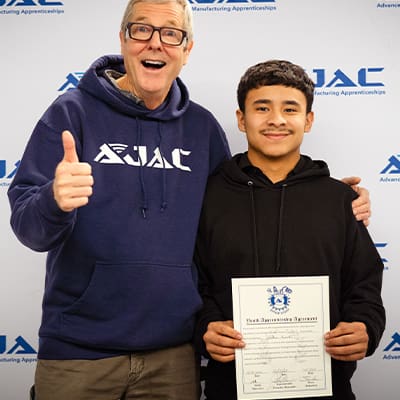

Seth Hamilton was nearing his 17th birthday and knew he wasn’t going to college. His after-high-school plans did not involve a four-year institution. Rising student loans and lack of finances steered Seth away from the popular choice of college and universities. As a junior at Lincoln High School, Seth enrolled in AJAC’s first Youth Apprenticeship program for high school students. One year later, Seth, along with Sean Colyer, another youth apprentice, are set to graduate and become Washington State’s first youth apprentice graduates this June.

During a visit from Governor Inslee in April, four of AJAC’s youth apprentices, along with their respective employers, toured the Governor around their shop floor highlighting the impact Youth Apprenticeship has made. “We started years ago trying to recruit younger people,” said Marianne Eveland, Production Manager at Quality Stamping & Machining. “This program allows the community to have extra help recruiting the right type of people.” A thorough vetting process designed by AJAC and local employers provided companies a platform to find the right candidates who have a focus on growing their skill set in manufacturing, whether it be machining, engineering, or fabrication.

Seth Hamilton, one of AJAC’s first Youth Apprentice graduates, prepares his HAAS CNC machine for a new part.

During the recruitment process at all ten Tacoma public high schools, Hamilton showed a strong interest in manufacturing. Lincoln High School, known locally for its outstanding shop class, laid the foundation for his success at American Structures & Design. Although he worked with manual machines in high school, Hamilton soon developed a new-found-love for Computer Numerical Controlled (CNC) machines, “Working on CNC machines is pretty intimate. It can be tedious at times, but you’re not doing the same thing every day. It has a lot of different things that can happen, different things you have to look for. It keeps the job interesting, it keeps your brain working.”

What else are we going to build and how else are we going to build this company? Knowing today, it’s going to be with the younger guys.” – Mark Weissenbuehler, President of American Structures & Design

Sean Colyer, another Lincoln High School graduate, works alongside Seth at American Structures & Design in the machining department. Unlike Seth, Sean did not take shop class during his time in high school. However, engineering class contributed to his success in AJAC’s Youth Apprenticeship program. “What I’ve enjoyed doing at American Structures & Design is mainly work on machines and have the ability to do more than just machining,” Colyer said. “Engineer Design in high school helped me with knowing how AutoCAD works, which all of our drawings are based off of. It’s nice having the background of how the drawings are made while I look at the blueprint.”

Sean Colyer shakes Governor Inslee’s hand after learning about Sean’s new role at American Structures & Design.

Employing high school students on the shop floor can do more than help a company’s bottom line and hiring needs. It brings an added excitement. It enriches the morale of the shop floor from entry-level employees to the very top.

Mark Weissenbuehler, President of American Structures & Design, noticed the enthusiasm youth apprentices bring to manufacturing, “As we got involved with the youth apprentices, and the younger generation, it was fun to watch them evolve, learn, and get excited. Which in return helped me learn and get excited,” Weissenbuehler said. “It filled the need for where my company is at and where we are going. What else are we going to build and how else are we going to build this company? Knowing today, it’s going to be with the younger guys.”

Sam Yost and Tanner Gerken, two Youth Apprentices at Quality Stamping & Machining, pose for a photo with Governor Jay Inslee.

The trend across America for employing the next generation is changing. No longer does every student fit into the same mold as a four-year, college-bound student. Too many jobs and opportunities are being passed simply because the experience of working in manufacturing isn’t made available. Youth Apprenticeship has made local companies in Washington State find the diamond in the ruff. The diamond in this case is a determined, well-mannered, motivated, and technologically advanced high school student. Youth Apprenticeship doesn’t have to be for someone who will never go to a four-year college, but it can be for anyone who wants to connect real-world skills with their personal interests and aspirations.

Hamilton and Colyer are set to graduate on June 22nd as Production Technicians Youth Apprentices. The road to manufacturing has been paved, but their journey is far from over. After their requirements are met, Hamilton and Colyer will enroll in AJAC’s Machinist (Aircraft Oriented) apprenticeship program to continue their education and on-the-job training. But where would they be today if this opportunity didn’t exist?

“I hope as more and more people find out about this program, especially if they are younger in high school like I was, to seriously think about it. If you have a little experience, and you like it, you can start making money right away. Kick start your life rather than wait around for ten years, not knowing what to do,” Hamilton explained. “The fact I get paid to take college courses, is the exact opposite of what it normally is, it’s pretty cool, I like it a lot. But I honestly don’t know where I would be today.”

View photos from Governor Inslee’s visit on AJAC’s Flickr page.