CNC Programmers play a vital role in manufacturing by turning blueprints and designs into precise instructions for computer-controlled machines. These programs tell lathes, mills, and other tools exactly how to cut, drill, and shape raw materials into finished parts.

What is a CNC Programmer?

Program Overview

Train for a Career as a CNC Programmer

As a CNC Programmer apprentice, you’ll learn how to use advanced CAD and CAM tools to design tooling and write code that drives precision machining of parts.

You’ll be at the intersection of design and manufacturing — translating engineering drawings into machine‑ready programs and ensuring parts come out right the first time.

| Program Length | 3-Years |

| On-the-Job Hours | 6,000 |

| College Classes | 9 |

| College Credits | 45 |

Hands-On Training That Builds Real Skills

As a CNC Programmer apprentice, you’ll learn how to think like a problem-solver and program like a professional.

You’ll build skills in:

- Developing tooling and fixturing to optimize manufacturing flow

- Creating CNC code and verifying numeric code using software platforms

- Reading engineering drawings, understanding part tolerances and designing for manufacturability

- Managing manufacturing data, documenting set‑up information, and collaborating with cross‑functional teams

- Using CAD/CAM systems to generate tool paths, simulate machining, and troubleshoot processes

By the end of the program, you’ll have the skills to program and optimize CNC machines, collaborate with engineers, and lead production workflows — setting you up for a long-term career in advanced manufacturing.

Why Apprenticeship Makes Sense

Hands-On Training with Real Employers

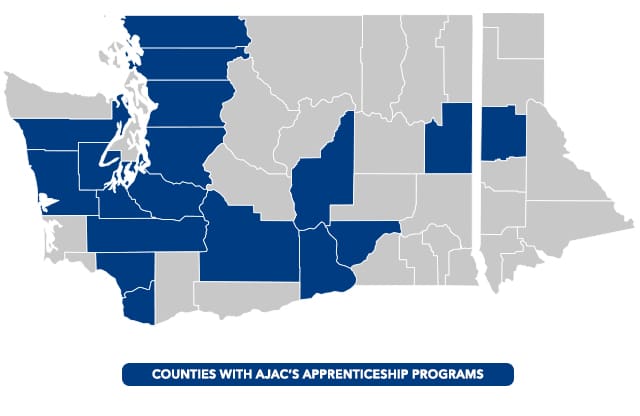

AJAC has partnered with 300+ advanced manufacturers to provide supervised, structured, paid on-the-job training.

AJAC apprentices can only work for companies that agree to hire them and place them into the program.

Each company has their own methodology for who they select as an apprentice.

Earn a Paycheck While You Learn

This advanced apprenticeship offers you the chance to earn while you learn and step into a high‑tech role in manufacturing.

Program Highlights:

- Paid on‑the‑job training at a partner employer

- 50% reduced tuition (many employers cover full cost)

- 45 college credits (9 classes × 5 credits each)

- Get a nationally recognized journey‑level credential

- Open pathways into roles such as Tool & Die Maker, Maintenance Manager, or Operations Manager AJAC

- Work with cutting‑edge manufacturing tools and software

*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location.

Apprenticeship Classes

CNC Programmer apprentices take 6 college-level classes (or 9 college-level classes if you are not a journey-level machinist). Classes are held one evening per week (Tuesday–Thursday, 5–9 PM) and is primarily online via Zoom for this program. Tuition: $400 per class (50% reduced rate). Many employers pay the full cost.

Learn to read and interpret engineering drawings and schematics, as well as practice basic drafting. Drawings studied in this class will come both from the text and from industry, and will include machining, fabrication, assemblies, and fluid power systems (only for Automation/Maintenance program).

This course focuses on the fundamentals and applications of geometry and trigonometry. Topics include perimeters, areas, volume, trigonometric ratios and function, right angles and non-right angles. Apprentices will discuss relationships of lines, planes, angles, congruent and similar triangles, polygons and circles while performing geometric and trigonometric functions as they relate to manufacturing and aerospace. Other topics include special triangles and the Pythagorean Theorem.

Apprentices will study the theory and application of the use of standard tolerances and GD&T concentrating on geometric dimensioning and its relation to engineering drawings.

In this course, students learn foundational CAD skills such as data management, validation, drawing arts and tooling that are essential for CNC Programmers.

Foundational CAD skills such as data management, validation, drawing arts and tooling that are essential for CNC Programmers. Work-holding solutions for each manufacturing sequence, develop jigs to aid manufacturing process, establish 3D data sets for each work-holding sequence, create bill of materials lists, design custom cutting tools, create set-up documentation etc.

Confirming customer requirements, defining manufacturing sequences, performing risk assessments to identify manufacturing issues, selecting tools, and documentation.

Use 2D and 3D CAD to create basic tool paths for both mills and lathes. Apprentices will create and verify CNC code, develop set-up documentation, and verify manufacturing data meets current engineering revisions.

Create basic macro programs, sub programs, subroutine programs and 3 + 12 axis programming Multi-axis CAM tool paths for mills and lathes and indexing. Apprentices will create CNC code, verify CNC code, and develop set-up documentation for more advanced machines and projects.

How to choose the specific tooling for the job based on the complex material being used, and create tool list documentation procedures. They will calculate cycle times and record cycle times, to understand job scope.

Program Entry-Points

This program is designed as a training for journey level Machinists. It has been structured as a 4,000 hour program for journey-level machinist graduates or those with a college certificate/degree.

For individuals with at least 5 years of proven machining experience, this is a 6,000 hour program to accommodate experienced Machinists achieving their journey level status through work experience but lacking formal academic preparation.

Based on subject matter experts and employer recommendations, the following is the candidate eligibility criteria:

- Apprenticeship Completion: Journey-Level Machinist. Automatically awarded first year course work (3 classes) and 2,000 OJT Hours.

- College Certificate or Degree + Industry Trained | 5 Years of Experience/Certificate or Degree: Up to 2 classes of the first year’s coursework and 1,500 OJT Hours.

- Industry Trained | 5+ Years of Proven Machining Experience: Required to complete all 9 RSI Classes and 6,000 OJT Hours.

| Apprenticeship Class | Apprenticeship Completion | Industry Trained | College + Industry Experience |

|---|---|---|---|

| YEAR 1 | |||

| APM 103: Engineering Drawings | O | X | TBD |

| APM 122: Geometry & Trigonometry | O | X | TBD |

| APM 201: GD&T | O | X | TBD |

| YEAR 2 | |||

| CNC 201: CAD Fundamentals | X | X | X |

| CNC 202: Design for Manufacturability | X | X | X |

| CNC 203: Manufacturing Processes Related to Project Management | X | X | X |

| YEAR 3 | |||

| CNC 204: Basic Tool Path for Mill & Lathe | X | X | X |

| CNC 205: Multi Axis/Indexing | X | X | X |

| CNC 206: Advanced CNC Programming Techniques | X | X | X |

| TOTAL CLASSROOM HOURS: 450 | |||

6,000 Hours of Hands-On Experience

Apprentices gain hands-on experience with structured tasks to ensure well-rounded expertise. The 6,000 hours (or 4,000 hours if you are a journey-level machinist) will be completed over the course of the apprenticeship. .

| OJT Competency | Approx. OJT Hours |

|---|---|

| Advance CNC Set-Up & Operations (4-axis, 5-axis process) | 2,600 |

| Material Process, Quality Assurance and Cutting Technology | 550 |

| Advance Inspection, Parts Finishing, Deburr and Administrative Work | 300 |

| Establish Manufacturing Process and Develop Tooling | 1,050 |

| Create CNC/NC Code, Identify Numeric Code | 1,000 |

| Develop Set-Up Documentation and Manage Manufacturing Data | 300 |

| Provide Internal/External Customer Service | 200 |

| TOTAL HOURS | 6,000 |

Step to Becoming an Apprentice

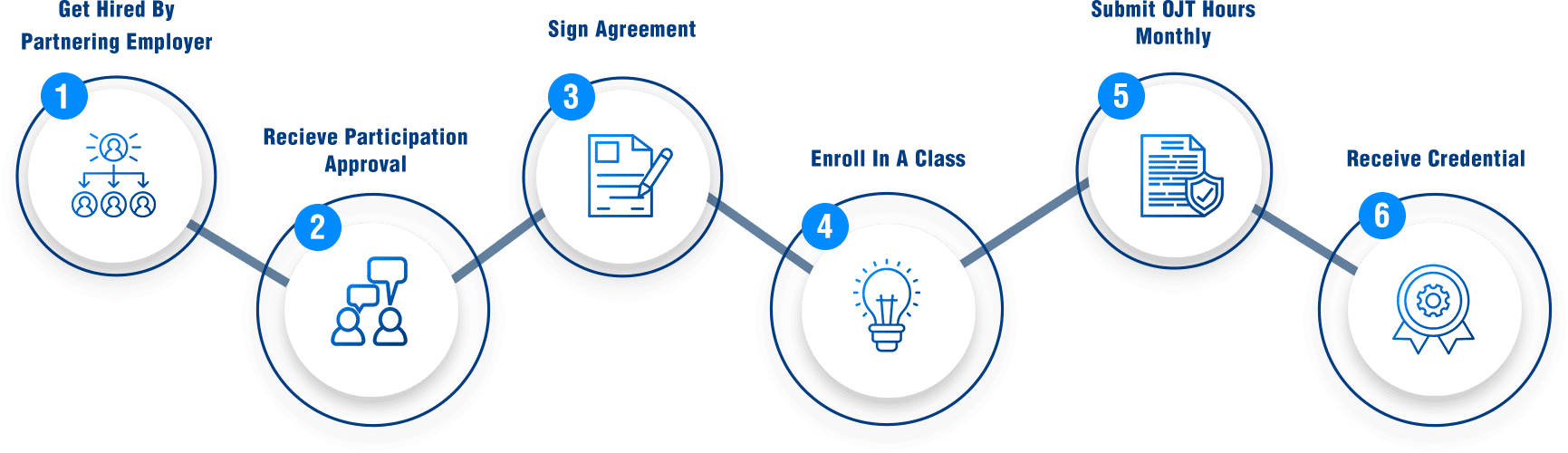

6 Steps to Becoming an Apprentice

Find an Employer Partner: Apply to a company already partnered with AJAC — or, if your employer isn’t yet a partner, they can easily join the program. The process is simple and AJAC will guide them through every step.

Get Company Approval: Your supervisor signs off on apprenticeship participation.

Sign the Apprenticeship Agreement: AJAC visits your employer to finalize.

Start Classes: Enroll in your first college-level course.

Track Hours: Log on-the-job training through AJAC’s Apprentice Tracking System.

Graduate: Earn your Journey-Level Certificate and AJAC Certificate of Completion.

Your Career Starts Here

Ready to create manufacturing programs, drive precision production, and develop a high‑skilled, high‑paying career? Join the CNC Programmer apprenticeship with AJAC — earn while you learn, gain valuable college credits, and achieve a nationally recognized credential.