Build advanced manufacturing expertise in plastics processing — earn while you learn, gain 6,000 hours of hands-on training and a nationally-recognized credential.

Launch Your Career

Program Overview

Train for a Career in Plastics Manufacturing

Plastic Process Technicians are skilled operators who run, monitor, and troubleshoot plastic injection molding machines.

This program builds expertise in machinery setup, troubleshooting, and scientific molding — preparing you for a long-term career in advanced manufacturing.

| Program Length | 3-Years |

| On-the-Job Hours | 6,000 |

| College Classes | 9 |

| College Credits | 45 |

Hands-On Skills for Advanced Manufacturing

Plastic Process Technicians are hands-on experts who ensure products meet quality standards while maintaining production efficiency. You’ll learn to:

- Set up and start injection molding machines, read blueprints, and check parts with calipers and optical comparators

- Monitor and troubleshoot processing problems, perform preventive maintenance, and document process changes

- Provide feedback on mold design and assist tool and die makers for optimal cycle times

- Apply scientific molding principles and minimize material scrap

- Operate and maintain connected automated systems safely

Every production line needs skilled technicians who understand both the machines and the materials — that’s your role.

Why Apprenticeship Makes Sense

Where You’ll Work

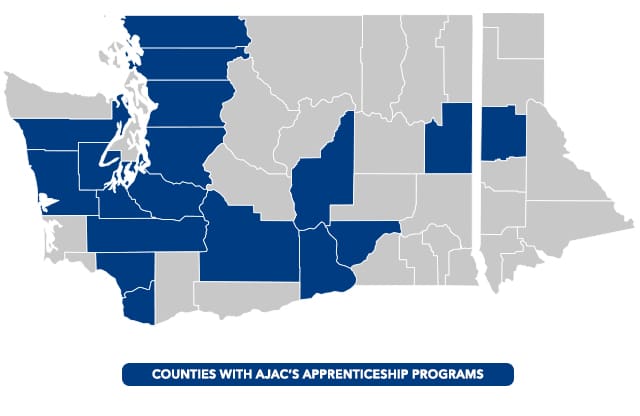

AJAC partners with 300+ advanced manufacturers in Washington and Idaho for structured, supervised, paid training.

Apprentices work only with employers who agree to enroll them in the program. Each company selects apprentices according to their own hiring methods.

Industries Include:

- Plastic injection molding & tooling

- Automated manufacturing & robotics

- Industrial equipment production

Earn a Paycheck While You Learn

This apprenticeship builds advanced skills in machining, maintenance, and troubleshooting — giving you a strong foundation in manufacturing technology.

Program Highlights:

- Earn while you learn — paid on-the-job training

- 50% reduced tuition (many employers cover 100%)

- 30+ college credits upon completion

- Nationally recognized journey-level credential

- Career paths into mechanical engineering, maintenance management, or industrial engineering

- Hands-on experience with cutting-edge plastics equipment

*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location.

Apprenticeship Classes

Classes are held one evening per week (Tuesday–Thursday, 5–9 PM) and are available online or in person at local colleges, high schools, or skill centers. Tuition: $400 per class (50% reduced rate). Many employers pay the full cost.

Review of basic arithmetic, basic algebra application, based on geometry, right angle trigonometry, oblique angle trigonometry, and right angles.

Learn to read and interpret engineering drawings and schematics, as well as practice basic drafting. Drawings studied in this class will come both from the text and from industry, and will include machining, fabrication, assemblies, and fluid power systems (only for Automation/Maintenance program).

Measuring and inspection of size, position, form, surface finish and orientation.

Apprentices will study the theory and application of the use of standard tolerances and GD&T concentrating on geometric dimensioning and its relation to engineering drawings.

In this course, apprentices will learn about industrial electrical theory, components, and equipment necessary to troubleshoot electrical problems. Apprentices will begin by learning to interpret electrical symbols, diagrams, and terminology.

Learn to maintain all of the elements of a mechanical system. Apprentices will begin by exploring mechanical fundamentals such energy, mechanical forces, and simple machines. Apprentices will learn to troubleshoot, assemble, and maintain couplings, gears, pulleys, chains, sprockets, and brakes.

Apprentices will explore the fundamentals of fluid power systems, including structures and components, operation, safety, as well as interpreting related standards, symbols, and diagrams. Hydraulic fluid types, properties, handling, and maintenance topics will be covered.

Plastics processing apprentices will explore material science and processing principles for polymer materials. Apprentices will learn about the chemical composition, structure, and material properties of polymers, and how polymer materials are modified to achieve desired properties.

Exploration of the materials, processes, and mold design principles for injection molding, compression molding, transfer molding, and die casting.

6,000 Hours of Hands-On Experience

Apprentices gain hands-on experience with structured tasks to ensure well-rounded expertise:

| OJT Competency | Approx. OJT Hours |

|---|---|

| Mold Setting & Process Set Up | 700 |

| Material Handling | 600 |

| Molding Machine Maintenance | 300 |

| Tool Maintenance | 300 |

| Safety | 100 |

| Quality Systems & Inspection | 500 |

| Assembly Equipment Operation & Bench Work | 500 |

| Process Development & Documentation (Molding) | 3,000 |

| TOTAL HOURS | 6,000 |

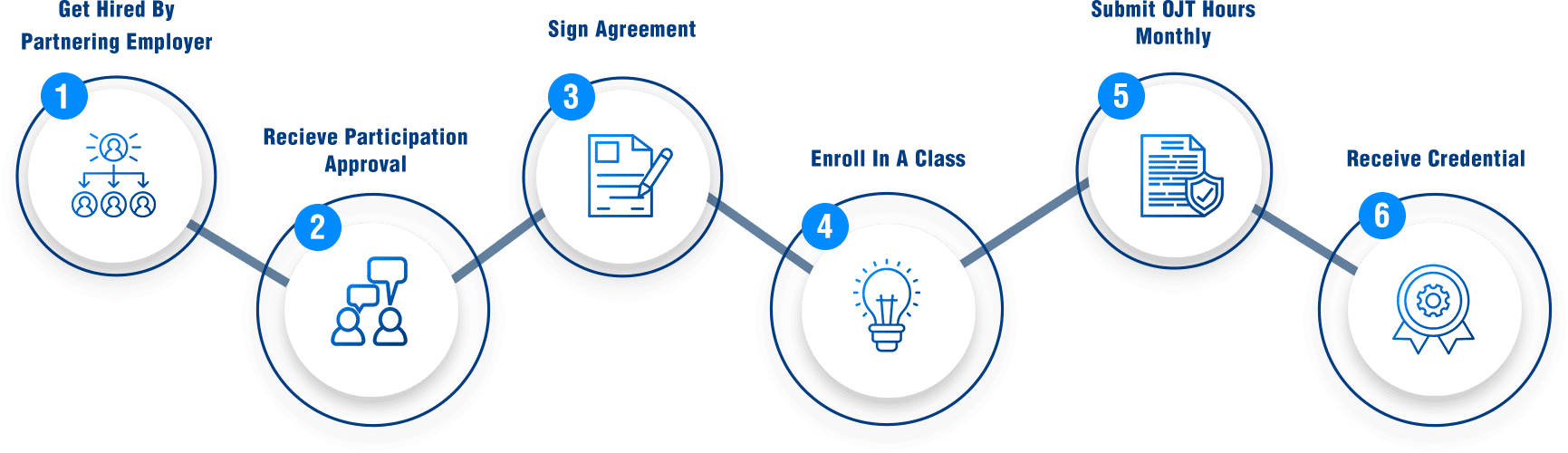

Steps to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Find an Employer Partner: Apply to a company already partnered with AJAC — or, if your employer isn’t yet a partner, they can easily join the program. The process is simple and AJAC will guide them through every step.

Get Company Approval: Your supervisor signs off on apprenticeship participation.

Sign the Apprenticeship Agreement: AJAC visits your employer to finalize.

Start Classes: Enroll in your first college-level course.

Track Hours: Log on-the-job training through AJAC’s Apprentice Tracking System.

Graduate: Earn your Journey-Level Certificate and AJAC Certificate of Completion.

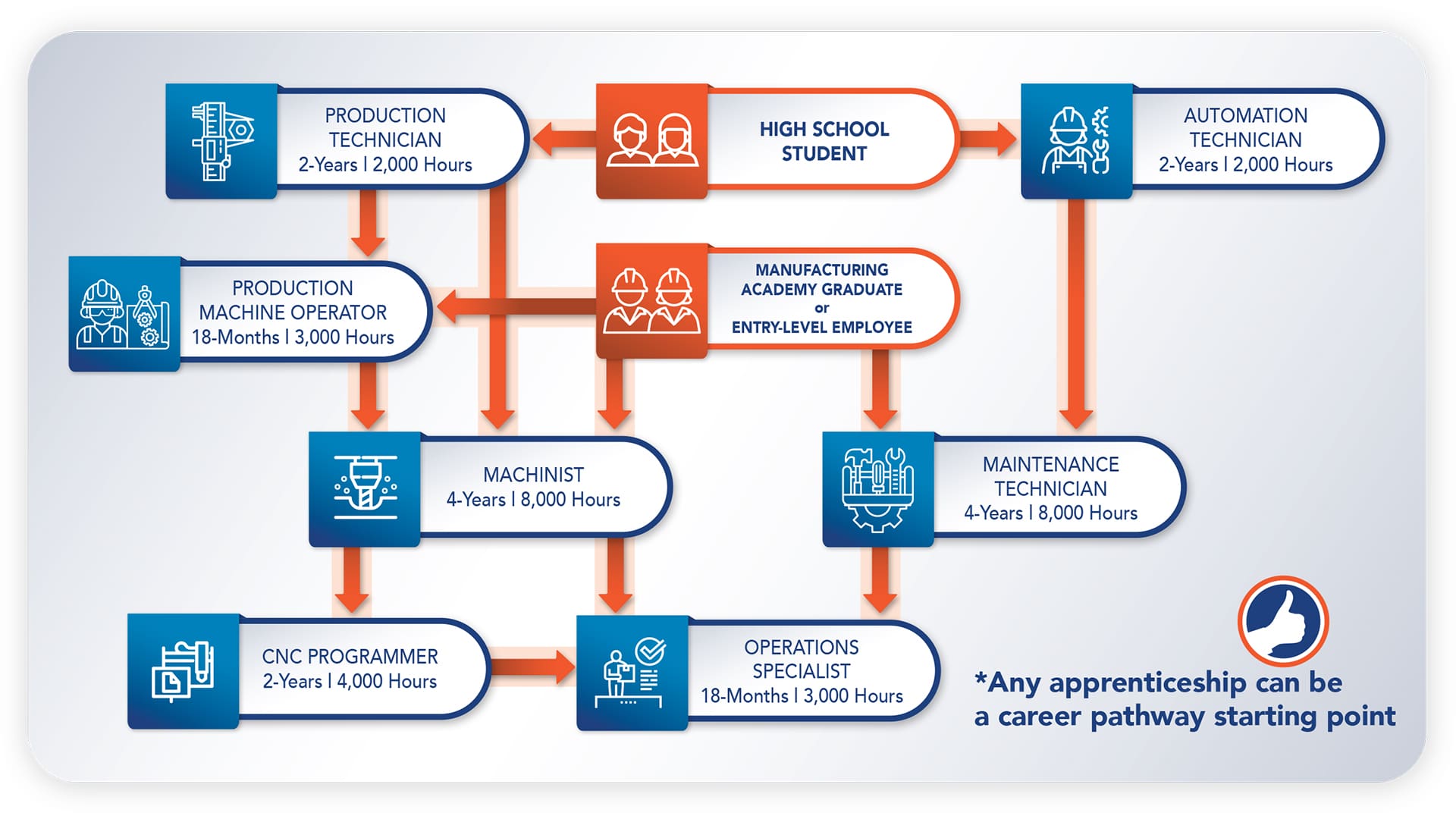

Start Small. Stack Big.

No matter where you begin—whether it’s running machines or maintaining equipment—AJAC’s Stackable Apprenticeships give you the power to keep climbing in your career pathway.

Start in an entry-level role and build your way into highly skilled, specialized, or even leadership positions—all without student debt. Each program builds on the last, helping you expand your skills, increase your earning potential, and take on new responsibilities—without putting your career on hold.

Launch Your Career Today!

Submit your information using the link below. After we receive your information, an AJAC representative will contact you for next steps. Please note, this is not an official application to become an apprentice. After a partnering employers agrees to enroll you in the program, you will officially apply and enroll at that time.