Almost every object you see—from a car component to an airplane part—contains precision pieces created by machinists.

What Does a Machinist Do?

Program Overview

Train for a Career as a Machinist

As a Machinist apprentice, you’ll work with high‑tech CNC machines, manual lathes and mills, and precision measuring tools to cut, shape, and finish components that keep manufacturing moving.

| Program Length | 4-Years |

| On-the-Job Hours | 8,000 |

| College Classes | 12 |

| College Credits | 60 |

Hands-On Training That Builds Real Skills

You’ll master the skills that turn raw materials into precision parts.

As an apprentice, you’ll learn to:

- Operate manual and computer‑numerical‑control (CNC) machine tools such as lathes and milling machines

- Read engineering drawings, interpret geometries and tolerances, and plan machining sequences

- Use precision measuring instruments (micrometers, calipers, optical comparators) to inspect finished parts

- Set up tooling and fixtures, create machining setups, and optimize cutting processes

- Understand machining materials (metals, plastics, composites), heat treatment, finishing operations

Every manufacturing environment relies on skilled machinists who can deliver precision and performance.

Why Apprenticeship Makes Sense

Hands-On Training with Real Employers

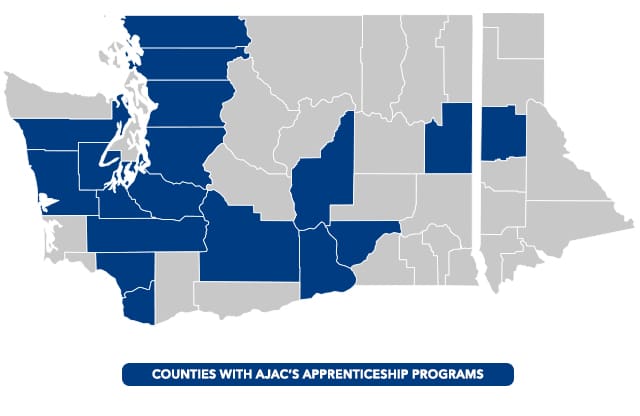

AJAC partners with 300+ advanced manufacturers in Washington and Idaho to provide supervised, structured, paid training.

Apprentices work only with employers that agree to hire and enroll them in the program. Each employer has its own selection process for apprentices.

Earn a Paycheck While You Learn

This advanced apprenticeship equips you with highly‑valued technical skills and opens up pathways to leadership and advanced manufacturing careers.

Program Highlights:

- Earn while you learn with paid on‑the‑job training

- 50% reduced tuition — many employers cover full cost

- Earn college credits (12 classes, 5 credits each = 60 credits)

- Earn a nationally‑recognized journey‑level credential

- Career advancement into roles such as CNC Programmer, Tool & Die Maker, Maintenance Technician

*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location.

Apprenticeship Classes

Classes are held one evening per week (Tuesday–Thursday, 5–9 PM) and are available online or in person at local colleges, high schools, or skill centers. Tuition: $400 per class (50% reduced rate). Many employers pay the full cost.

Fundamental manual machining skills and knowledge to include topics such as job plans, drawings, tolerances, engineering specifications and use of manual tools.

Intro to precision machining with a focus on basic, manual machining techniques including speeds and feeds, milling machine/drill press and lathes.

Learn to read and interpret engineering drawings and schematics, as well as practice basic drafting. Drawings studied in this class will come both from the text and from industry, and will include machining, fabrication, assemblies, and fluid power systems (only for Automation/Maintenance program).

Apprentices will develop a working knowledge and practical application of algebraic processes as they relate to manufacturing. They will identify and understand the applications of formulas to shop problems, learn to manipulate formulas, simplify expressions and solve linear equations. Discussions will include adding, subtracting, multiplying and dividing fractions, ratio, proportion and percentages. Number lines and Cartesian coordinates will also be covered.

This course focuses on the fundamentals and applications of geometry and trigonometry. Topics include perimeters, areas, volume, trigonometric ratios and function, right angles and non-right angles. Apprentices will discuss relationships of lines, planes, angles, congruent and similar triangles, polygons and circles while performing geometric and trigonometric functions as they relate to manufacturing and aerospace. Other topics include special triangles and the Pythagorean Theorem.

G&M programing, reading G&M code, XYZ coordinates, establishing tool length offsets (TLO), calculating changed data capture (CDC) and cutter radius compensation (CRC).

Apprentices will study the theory and application of the use of standard tolerances and GD&T concentrating on geometric dimensioning and its relation to engineering drawings.

Apprentices will hand write simple commands and basic programs for mills using G & M codes. They will learn basic Mastercam and use of verification software.

Apprentices will hand write simple commands and basic programs for lathes using G & M codes. They will learn basic Mastercam and use of verification software.

Comprehensive understanding of outside processes and the properties of materials that are governed by industry standards.

Measuring and inspection of size, position, form, surface finish and orientation.

Exploration of new, emerging and advancing technologies, including properties and machining of composites. Apprentices will learn more in depth about Lean manufacturing, machine preparation, advanced machining technologies such as EDM, Water Jet and Laser Stereolithography.

8,000 Hours of Hands-On Experience

Apprentices gain hands-on experience with structured tasks to ensure well-rounded expertise:

| OJT Competency | Approx. OJT Hours |

|---|---|

| Conventional & CNC Machining Basics | 2,600 |

| Conventional & CNC Machining Operations | 2,100 |

| CNC Setup and Advanced Operation Procedures | 800 |

| Material Process, Quality Assurance & Cutting Technology | 500 |

| Advanced Machining Techniques & NC Basic Programming | 500 |

| Inspection, Parts Finishing, Deburr, Assembly, Bench Work | 1,500 |

| TOTAL HOURS | 8,000 |

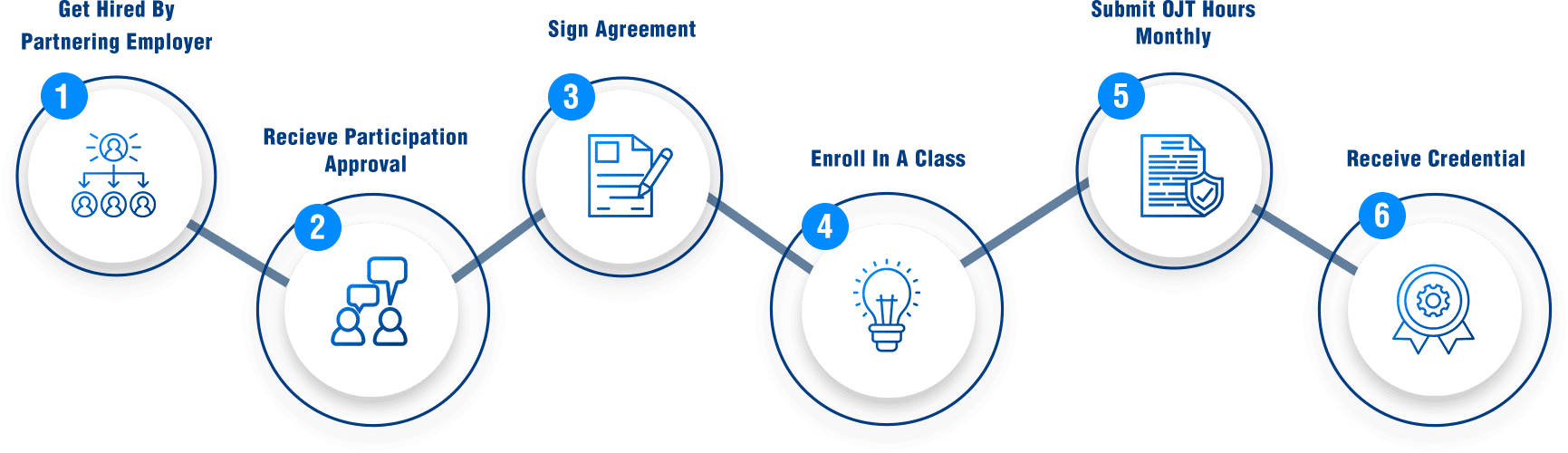

Steps to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Find an Employer Partner: Apply to a company already partnered with AJAC — or, if your employer isn’t yet a partner, they can easily join the program. The process is simple and AJAC will guide them through every step.

Get Company Approval: Your supervisor signs off on apprenticeship participation.

Sign the Apprenticeship Agreement: AJAC visits your employer to finalize.

Start Classes: Enroll in your first college-level course.

Track Hours: Log on-the-job training through AJAC’s Apprentice Tracking System.

Graduate: Earn your Journey-Level Certificate and AJAC Certificate of Completion.

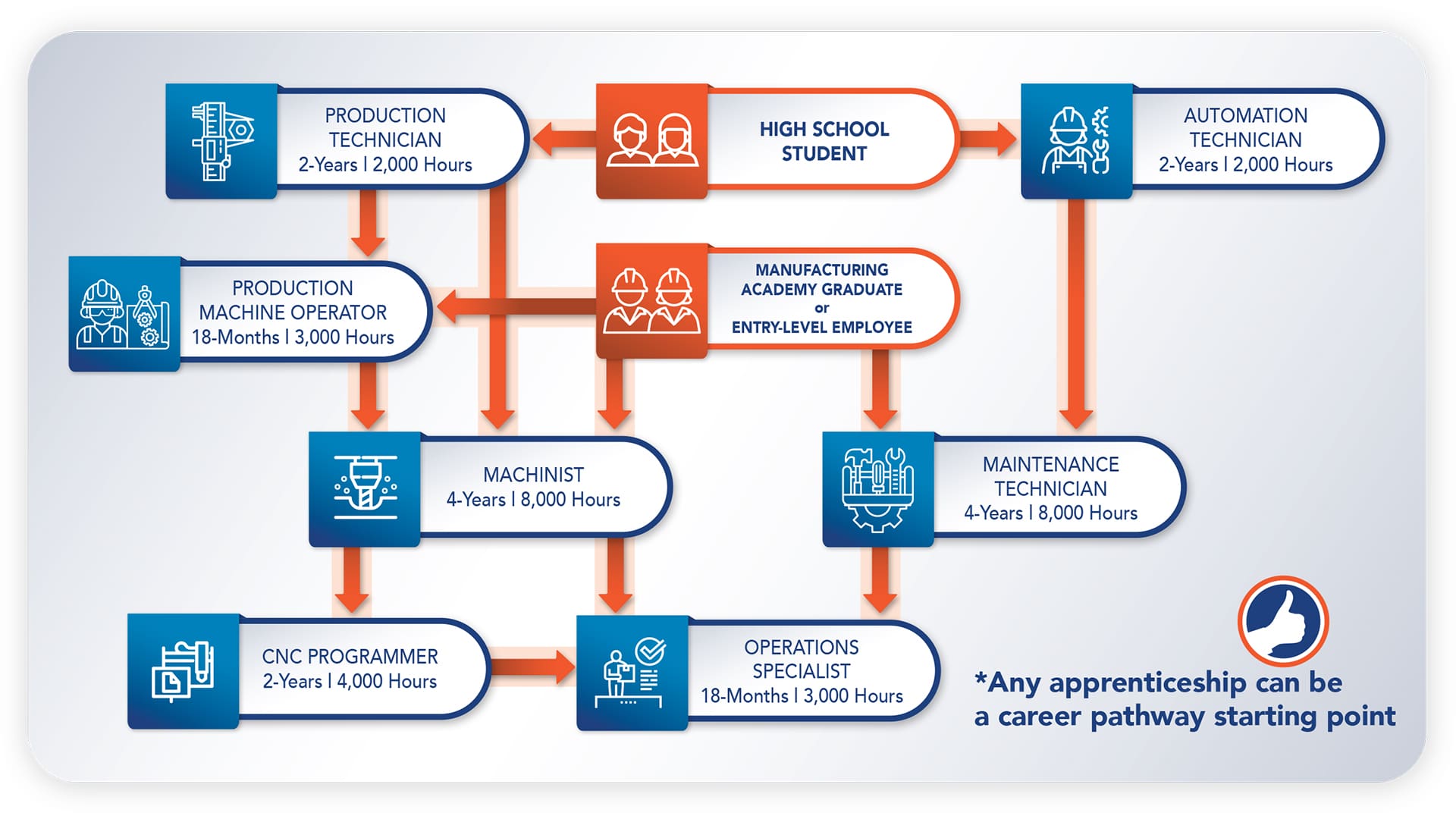

Start Small. Stack Big.

No matter where you begin—whether it’s running machines or maintaining equipment—AJAC’s Stackable Apprenticeships give you the power to keep climbing in your career pathway.

Start in an entry-level role and build your way into highly skilled, specialized, or even leadership positions—all without student debt. Each program builds on the last, helping you expand your skills, increase your earning potential, and take on new responsibilities—without putting your career on hold.

Your Career Starts Here

If you’re ready to build a hands‑on career with high‑earning potential, precision skills, and long‑term growth — join AJAC’s Machinist apprenticeship. Earn while you learn, gain college credits, and walk away with a nationally‑recognized credential — all without student debt.