November 9, 2021

Washington State Invests $3.8 Million in Aerospace Apprenticeship Expansion—AJAC Awarded $1.3 MillionAJAC is thrilled to announce we are the recipients of $1.3 million in grant funding through the Washington State Department of Labor & Industries’ “Aerospace Workforce Development Expansion” Grant.…

Read More

October 4, 2021

Berry Global Youth Internship ProgramBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

July 19, 2021

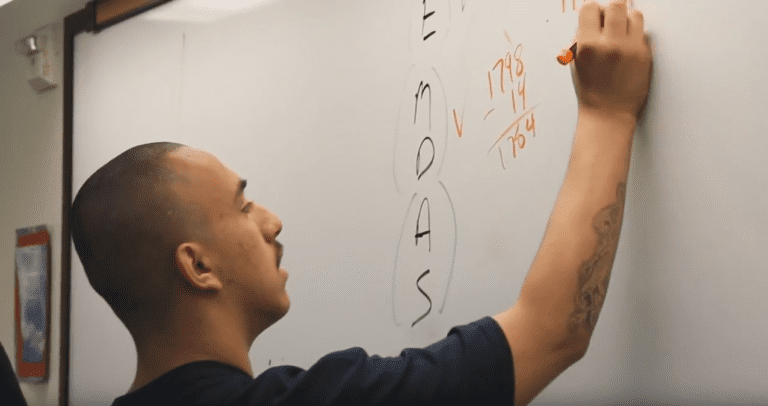

AJAC Trains Opportunity Youth for Manufacturing CareersBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

August 22, 2019

The Boy WonderWhen you walk into AJAC’s Manufacturing Academy at South Seattle College-Georgetown Campus the first thing you’ll notice is the intimidating computer numerical controlled (CNC) and manual machines scattered around the…

Read More

July 16, 2019

5 Questions With John ManningPlease welcome the newest addition to the AJAC family, John Manning. John has been hired as our new Apprenticeship Navigator serving primarily King and Pierce Counties. John will help navigate…

Read More

October 9, 2018

Manufacturing Day Is More Than Inspiring, It’s FamilyFamily based. Good pay. Good benefits. Those were the three takeaways from students who toured Buyken Metal Products last Thursday as part of a nationwide celebration of manufacturing. Manufacturing Day—occurring…

Read More

August 28, 2017

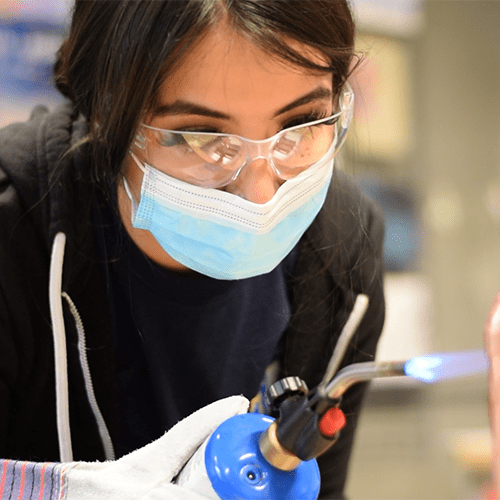

Manufacturing Academy Teaches Job-Ready Skills to Juvenile Rehabilitation Administration StudentsAJAC’s Manufacturing Academy has partnered with Juvenile Rehabilitation Administration and Pioneer Human Services this past year to offer young adults an opportunity to learn job-ready skills through the 12-week, pre-apprenticeship…

Read More

May 10, 2017

Meet Jim, AJAC’s Apprenticeship Preparation ManagerHe is a jack of all trades but he has mastered the perfect pizza combo. Meet AJAC’s new Apprenticeship Preparation Manager, Jim Johnson! What’s the best part of your job so…

Read More

September 16, 2016

Manufacturing Needs Women – So Let’s Train ThemThe Aerospace Joint Apprenticeship Committee, in partnership with the YWCA and South Seattle College hosted the first-ever Women in Manufacturing Symposium at South Seattle College – Georgetown Campus, highlighting…

Read More

August 29, 2016

AJAC’s ‘Manufacturing Academy’ Goes Full-Throttle With ‘Earn While You Learn’ ModelInternships can be a grueling yet necessary step most of us endure before we are accepted in the working world. In manufacturing, internships are far-and-few between – but one program…

Read More

August 29, 2016

Women in Manufacturing SymposiumJoin us for this forum and networking event introducing women to career and training opportunities in the exciting and dynamic field of advanced manufacturing. Hear from a panel of women…

Read More

August 29, 2016

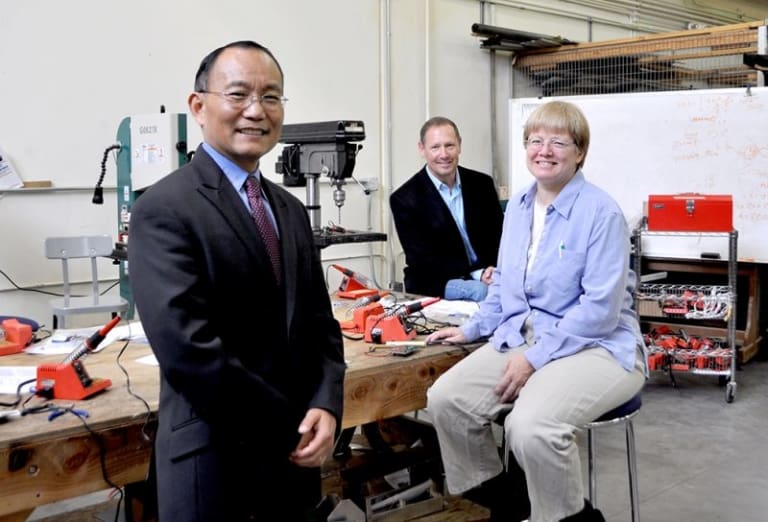

Senator Patty Murray Visits Manufacturing AcademySenator Patty Murray stopped by the Seattle Manufacturing Academy program on August 9th to discuss how the Workforce Innovation and Opportunity Act (WIOA) has helped undeserved and disadvantaged individuals to…

Read More