October 7, 2021

MFG Day 21 with Pexco AerospaceLaunched annually on the first Friday in October with events that continue throughout the month, MFG Day helps show the reality of modern manufacturing careers by encouraging thousands of…

Read More

July 19, 2021

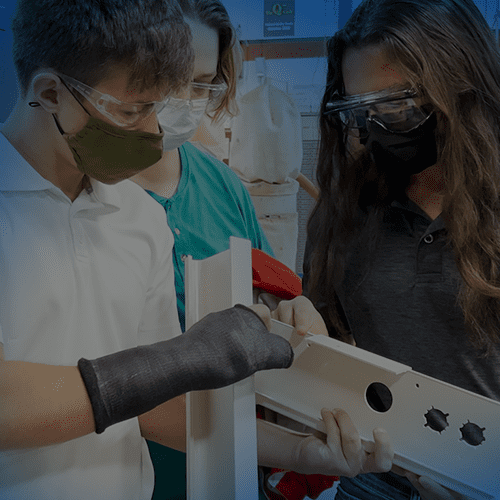

AJAC Trains Opportunity Youth for Manufacturing CareersBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

April 2, 2021

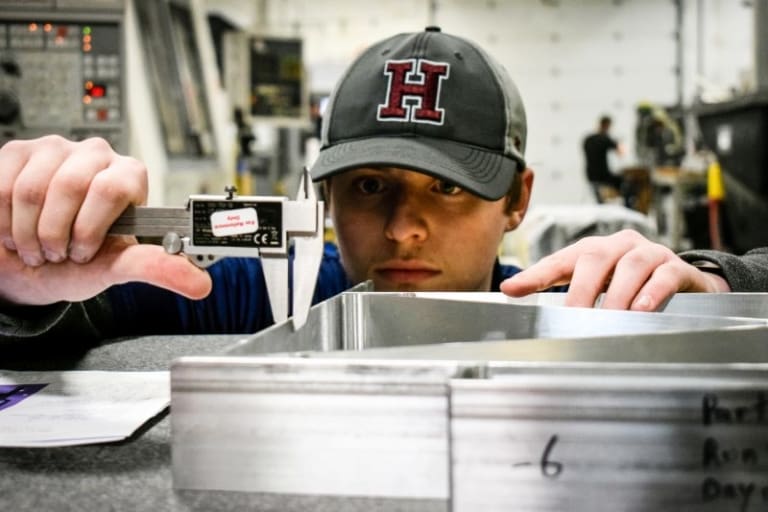

Youth Apprenticeship Spokane | WEMCO, Inc.Meet Connor Snell, a Production Technician (Youth Apprentice) through the Aerospace Joint Apprenticeship Committee (AJAC). Connor launched his career in manufacturing after receiving an offer from WEMCO, Inc., a Spokane-based…

Read More

February 26, 2021

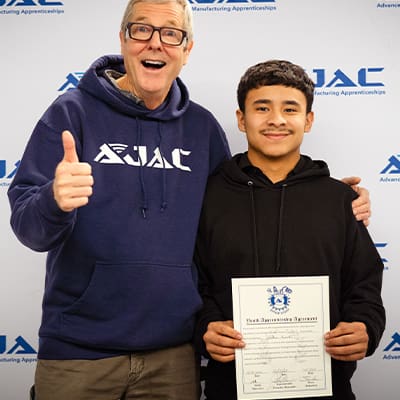

AJAC Youth Apprentice Featured in STEM NewsletterHector Martinez enrolled in AJAC’s two-year Automation Technician (Youth) Apprenticeship program in 2019 after receiving an offer from Yakima Chief Hops. Hector went to Toppenish High School and was also…

Read More

February 23, 2021

AJAC Featured in Aspen Institute Work-Based Learning ReportAmerica’s youngest workers, particularly young adults of color, are facing the most dire employment prospects since the Great Depression. As our nation looks toward recovery, and policymakers and investors seek…

Read More

October 2, 2020

Becoming A Youth Apprentice in a Small TownMeet Noah Retallic, a 17 year-old Automation Technician Youth Apprentice through the Aerospace Joint Apprenticeship Committee (AJAC). Noah enrolled in the Youth Apprenticeship in Spring 2020 and immediately began his…

Read More

October 8, 2019

MFG Day (Manufacturing Day) 2019 | AJAC & Machinists Inc.Take a tour of Machinist Inc in Seattle, Washington as the Aerospace Joint Apprenticeship Committee (AJAC) and Hazen High School (Renton School District) celebrate National Manufacturing Day (MFG Day) 2019.…

Read More

July 11, 2019

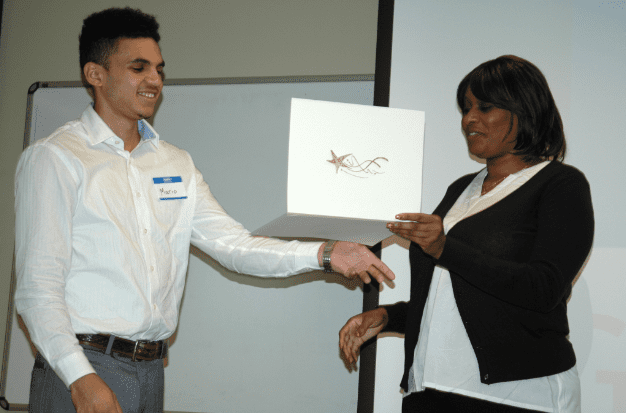

2019 Washington Youth Apprenticeship Signing DayOn June 28, 2019, nearly 100 newly registered Youth Apprentices from across Washington State celebrated the beginning of their apprenticeship at the ShoWare Center in Kent, Washington. Signing Day brought…

Read More

June 6, 2019

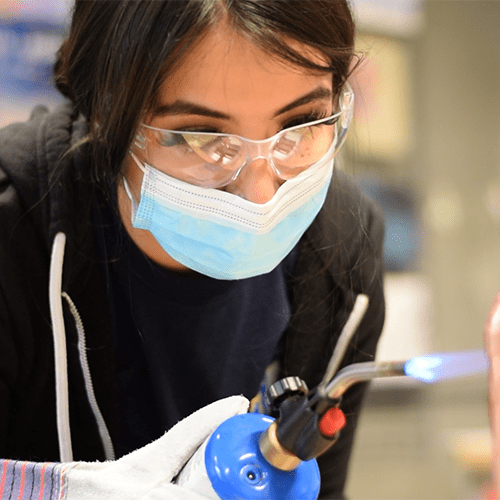

An Ordinary Teenager in an Extraordinary ApprenticeshipIt’s six in the morning at Tool Gauge, a Tacoma, Washington manufacturer that creates complex, high-quality plastic and metal parts and assemblies for the global aerospace industry. In walks a…

Read More

February 18, 2019

AJAC Youth Apprenticeship: Breaking the MoldNew Video Provides a Cinematic Look at Registered Youth Apprenticeship in Washington State. SEATTLE, WA-Washington State Governor Jay Inslee calls it the “supply train for the supply chain”. Aerospace and…

Read More

October 26, 2018

Governor Inslee Visits Cadence Aerospace & Youth ApprenticesDuring a private meeting at Cadence Aerospace, Governor Inslee and his staff met with representatives from the aerospace manufacturer, AJAC and current Youth Apprentices to discuss how the registered Youth…

Read More

July 3, 2018

2018 Youth Apprenticeship Signing Day CeremonyOn June 27, 2018, 67 newly registered Youth Apprentices signed their letter of agreement signifying a commitment to work in the aerospace and advanced manufacturing industries through the Aerospace Joint…

Read More

May 7, 2018

One Year In, AJAC Youth Apprentices Set To Graduate This JuneSeth Hamilton was nearing his 17th birthday and knew he wasn’t going to college. His after-high-school plans did not involve a four-year institution. Rising student loans and lack of finances…

Read More

February 1, 2018

Focus Shifts to Broadening Youth Apprenticeships During 2018 Governor’s Youth Apprenticeship SummitApprenticeships are not an alternative to higher education. It is higher education. This sentiment rang loud and true during the 2018 Governor’s Youth Apprenticeship Summit, which in its second year,…

Read More

December 12, 2017

Youth Apprenticeship: The Journey BeginsOn October 16, 2017, Washington State Governor Jay Inslee met with the partners, community organizations and local-area employers to discuss how the first year of Youth Apprenticeship has gone. The…

Read More

November 29, 2017

Gensco MFG Day 2017 (Video)On October 6, 2017, students from the Tacoma Public Schools (TPS) toured Gensco, Inc. as part of Manufacturing Day. Manufacturing Day is a celebration of modern manufacturing meant to inspire…

Read More

July 7, 2017

Youth Apprenticeship Webinar & PowerPointWashington STEM, Washington State Department of Labor and Industries (L&I) and AJAC gave a joint presentation on all-things Youth Apprenticeship during a live webinar on June 26, 2017. Josie Bryan…

Read More

June 29, 2017

Manufacturing is STEM: Providing Career Connected LearningIn partnership with the Office of the Governor, the Workforce Board, WSU Extension, and the Office of the Superintendent of Public Instruction, Washington STEM traveled across the state to explore…

Read More

May 3, 2017

Yakima Ushers In First Youth ApprenticesYakima’s West Valley High School was given the baton last week to launch their first AJAC Youth Apprenticeship program. High school juniors Trevor Mackey, Osborne Rogers, and Bradley Ethier individually…

Read More

April 17, 2017

AJAC to Participate in Grays Harbor Career Pathway DayOn Monday, April 24, Grays Harbor Youth Works, Greater Grays Harbor, Inc., Aerospace Joint Apprenticeship Committee, and Grays Harbor College worked together to provide North Beach and Lake Quinault High…

Read More

April 10, 2017

Tacoma Celebrates First High School Apprentices During National Signing DayAll eyes were on Pacific Machine last week as the city of Tacoma ushered in a new era of career-connected learning. The decade-old mindset of ‘every student should attend a…

Read More

March 13, 2017

AJAC’s Youth Apprenticeship Featured on City of Tacoma’s ‘CityLine’ TV ShowAJAC’s Youth Apprenticeship program continues to garner attention across our region as the first group of students prepare to begin their apprenticeship in high school. Seth Hamilton, one of our…

Read More

January 23, 2017

Washington State Approves Governor Inslee’s Youth Apprenticeship ProgramFrom left to right: John Page from Tacoma Public School, Kristi Grassman, AJAC, Lynn Strickland, AJAC, Jesse Cote from IAM 751 and Sandra Husbands, L&I at the Washington Apprenticeship Training Council…

Read More

November 4, 2016

Washington State to Launch First-Ever Youth Apprenticeship Program For High-Demand Industries(From left to right) Governor Jay Inslee, Lynn Strickland and Jesse Milbrath Over the last two years, the Aerospace Joint Apprenticeship Committee, Washington State Department of Labor and Industries, the…

Read More

October 7, 2016

Manufacturing Day Opens Doors for The Next GenerationThe Aerospace Joint Apprenticeship Committee partnered with Training Agent Buyken Metal Products for the third annual Manufacturing Day in Kent, Washington. Over 40 students from Kentridge High School and Kent…

Read More

August 29, 2016

Goodwill Aerospace Students Gain Altitude With Early Start to Getting a JobTULALIP — When the Seattle Goodwill started its Youth Aerospace Program five years ago, it was aiming to take advantage of the high density of aerospace manufacturing expertise in…

Read More