November 9, 2021

Washington State Invests $3.8 Million in Aerospace Apprenticeship Expansion—AJAC Awarded $1.3 MillionAJAC is thrilled to announce we are the recipients of $1.3 million in grant funding through the Washington State Department of Labor & Industries’ “Aerospace Workforce Development Expansion” Grant.…

Read More

October 7, 2021

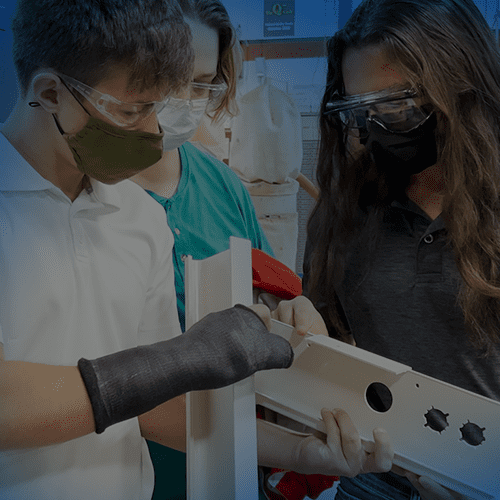

MFG Day 21 with Pexco AerospaceLaunched annually on the first Friday in October with events that continue throughout the month, MFG Day helps show the reality of modern manufacturing careers by encouraging thousands of…

Read More

October 4, 2021

Berry Global Youth Internship ProgramBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

September 17, 2021

AJAC Featured in Port of Seattle’s “Equity Index”The Equity Index was established to develop equity-based partnerships and provide resources and support in the most vulnerable, underfunded communities in King County. With the Equity Index, the Port employs…

Read More

August 23, 2021

Coffee Chats: Leveraging Apprenticeships to Strengthen Your WorkforceEconomic Alliance Snohomish County offers regular webinar’s through their Coffee Chat’s series. The topic on August 17th was Leveraging Apprenticeships to Strengthen Your Workforce. Participants included Angie Sievers, Snohomish STEM;…

Read More

July 20, 2021

AJAC Discusses Apprenticeships with PNAA & Tool GaugeThe Pacific Northwest Aerospace Alliance (PNAA) invited AJAC and Tool Gauge to their Factory Friday Tour event to discuss workforce training solutions including registered apprenticeship programs for advanced manufacturing. The…

Read More

July 19, 2021

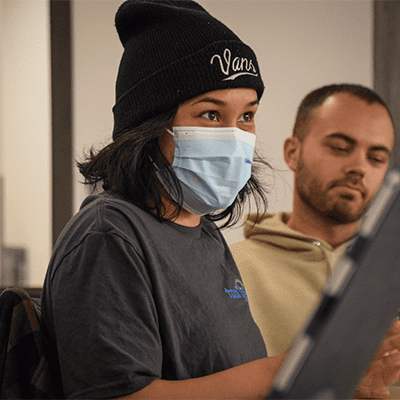

AJAC Trains Opportunity Youth for Manufacturing CareersBeginning in 2014, AJAC partnered with the Washington Department of Children, Youth and Families (DCYF) to provide a 12-week pre-apprenticeship training to incarcerated young men living in a DCYF transitional…

Read More

July 6, 2021

AJAC Celebrates 129 Graduates from the Class of 2020 & 2021On June 22nd, AJAC held its first virtual apprenticeship graduation ceremony for the Class of 2020 and 2021—ushering in 129 graduates across six different apprenticeship occupations. These 129 graduates represented…

Read More

May 7, 2021

2021 Youth Apprenticeship Info SessionTracey Turcotte, AJAC’s Youth Apprenticeship Manager held an information session for prospective Youth Apprentices interested in joining our programs for the 2021-2022 school year. AJAC currently operates two registered…

Read More

April 20, 2021

5 Questions With Leo VogelMeet AJAC’s new Financial Aid Manager, Leo Vogel. Leo comes to AJAC with over 12 years of experience in financial aid which spans career/adult education, private university education, and public/state…

Read More

April 2, 2021

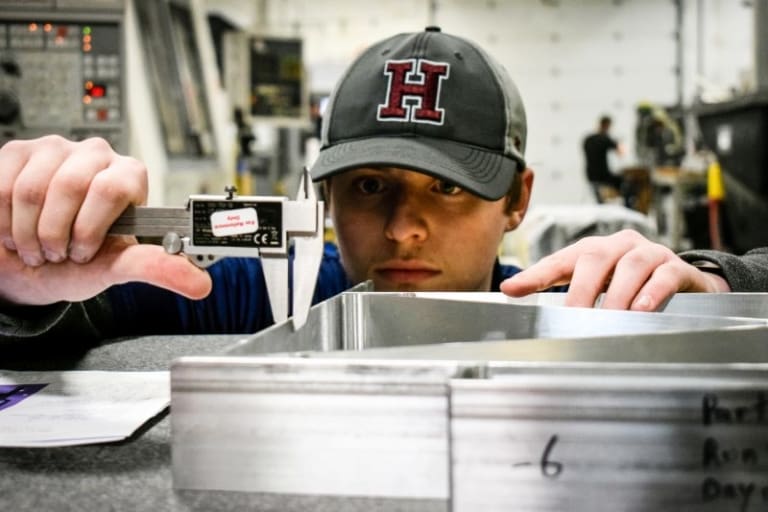

Youth Apprenticeship Spokane | WEMCO, Inc.Meet Connor Snell, a Production Technician (Youth Apprentice) through the Aerospace Joint Apprenticeship Committee (AJAC). Connor launched his career in manufacturing after receiving an offer from WEMCO, Inc., a Spokane-based…

Read More

March 22, 2021

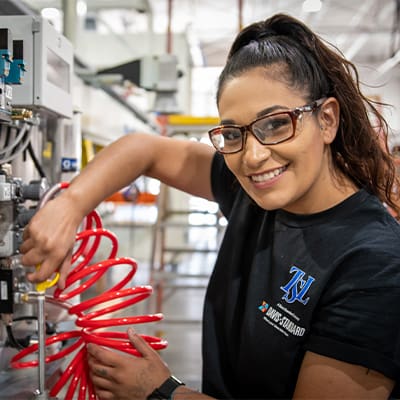

AJAC Apprentice Encourages More Women to Pursue ManufacturingAJAC Machinist apprentice, Mallory Martindale, was invited to speak on a panel regarding women in nontraditional occupations hosted by WANTO. Mallory is nearly complete with her four-year machining apprenticeship, and…

Read More

March 5, 2021

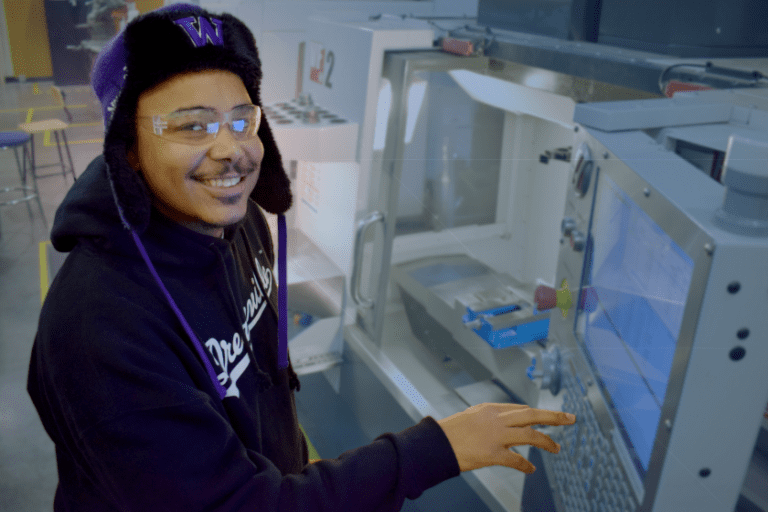

Blue Origin Apprentice Talks Manufacturing Academy & ApprenticeshipNyck Davis spent his afternoons measuring objects around his house. The COVID-19 pandemic forced Nyck to reimagine himself, not as a former automotive technician at Mercedes Benz, but as a…

Read More

March 4, 2021

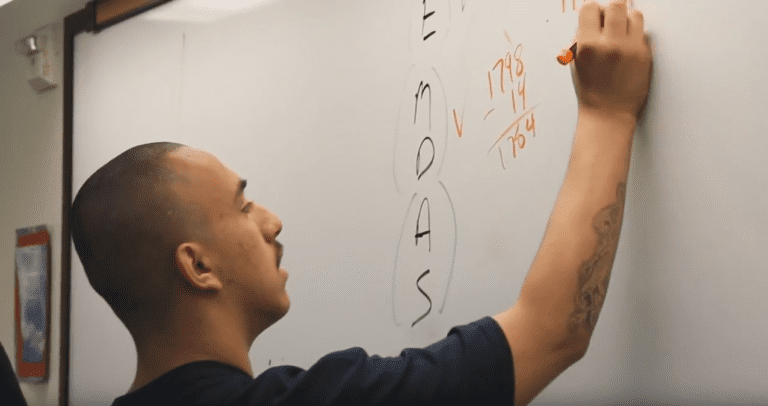

Instructor Goes Extra Mile in Juvenile RehabilitationThis article was originally written and published by the Washington State Department of Children, Youth, and Families (DCYF). One of the many benefits of youth placement in least restrictive community…

Read More

February 26, 2021

AJAC Youth Apprentice Featured in STEM NewsletterHector Martinez enrolled in AJAC’s two-year Automation Technician (Youth) Apprenticeship program in 2019 after receiving an offer from Yakima Chief Hops. Hector went to Toppenish High School and was also…

Read More

February 23, 2021

AJAC Featured in Aspen Institute Work-Based Learning ReportAmerica’s youngest workers, particularly young adults of color, are facing the most dire employment prospects since the Great Depression. As our nation looks toward recovery, and policymakers and investors seek…

Read More

January 21, 2021

AJAC Launches New CNC Programmer ApprenticeshipThe Aerospace Joint Apprenticeship Committee (AJAC) is excited to offer a new CNC Programmer Apprenticeship this spring! This program combines on-the-job training (OJT) with evening classes one night a week. AJAC…

Read More

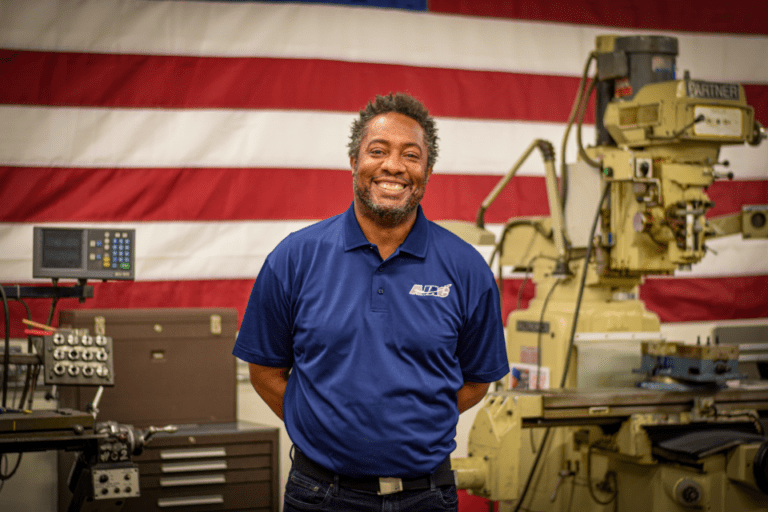

December 22, 2020

5 Questions with Lonnie FranklinWhat was the last experience that made you a stronger person? Making the move back to Seattle was something that made me a stronger person. Moving and going through a…

Read More

December 15, 2020

Why I Chose Manufacturing | Kailey HardingKailey Harding’s interest in manufacturing first peaked when she saw students making carbon fiber skateboards at the Pierce County Skills Center. As an avid longboarder, she was immediately drawn to…

Read More

December 7, 2020

5 Questions with Priscilla JohnsonWhat will your new role at AJAC include? My role here at AJAC will be teaching the Manufacturing Academy pre-apprenticeship program. I will be providing instructional training for individuals that…

Read More

November 30, 2020

She Was Ready for a Fresh Start, Now She’s Got a Fresh CareerShe was ready for a fresh start, now she’s got a fresh career | Renton Reporter Connect to training – and employers hungry for new talent – in advanced manufacturing.…

Read More

November 23, 2020

Lift off! Take your career from the launch pad to the stratosphereLift off! Take your career from the launch pad to the stratosphere | Kent Reporter Aurelia Greene has completed all of the college-level classwork for her Aerospace Joint Apprenticeship Committee…

Read More

November 12, 2020

One-on-One with Evan Thomas, AJAC Machinist GraduateTo celebrate National Apprenticeship Week 2020, AJAC sat down with former machinist graduate, Evan Thomas, for a candid interview about his apprenticeship experience. Our 24-minute conversation covered a wide variety…

Read More

November 9, 2020

Advanced Manufacturing Apprenticeships Launch Out-of-This-World OpportunitiesAdvanced manufacturing apprenticeships launch out-of-this-world opportunities | HeraldNet.com Mallory Martindale’s apprenticeship with the Aerospace Joint Apprenticeship Committee is almost complete. She’s been working in manufacturing since she graduated high school,…

Read More

October 2, 2020

Becoming A Youth Apprentice in a Small TownMeet Noah Retallic, a 17 year-old Automation Technician Youth Apprentice through the Aerospace Joint Apprenticeship Committee (AJAC). Noah enrolled in the Youth Apprenticeship in Spring 2020 and immediately began his…

Read More

September 23, 2020

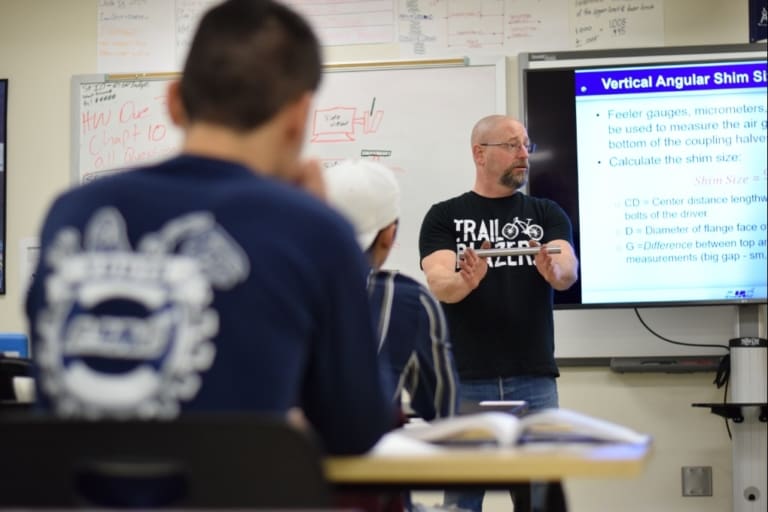

5 Questions With Stephen MatczakPlease welcome our newest Manufacturing Academy instructor, Stephen Matczak! In 2010, Stephen completed his machining degree at Perry Technical Institute in Yakima, Washington and in 2013 became one of the…

Read More

September 2, 2020

New Grants & Partnerships | Q1 & Q2 2020As a statewide, nonprofit 501(c)(3) aerospace and advanced manufacturing registered apprenticeship organization, AJAC raises public and private resources through grants and contracts on behalf of our mission to develop, implement…

Read More

May 27, 2020

AJAC To Offer New Low-Cost, Short-Term Trainings This July!New Lost-Cost, Short-Term Trainings From AJAC AJAC is excited to announce this July we will offer three consecutive short-term trainings at our Advanced Manufacturing Prep Training Center in Kent, Washington.…

Read More

May 15, 2020

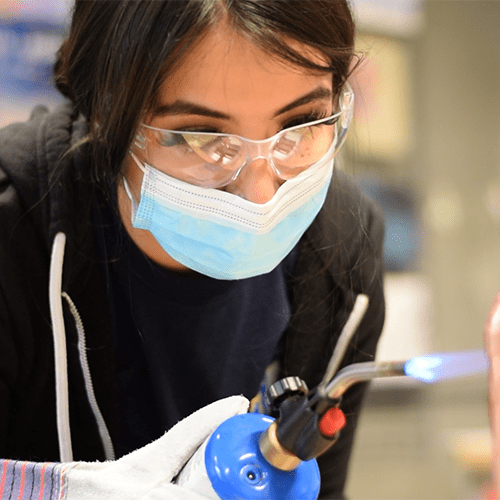

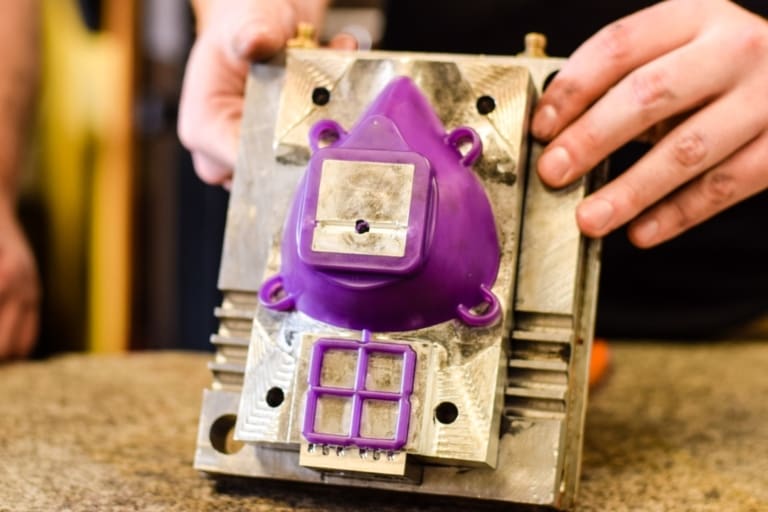

AJAC Apprentice Uses Training to Help Frontline Healthcare WorkersNathan Hall, a Tool & Die Maker Apprentice at SEA-LECT Plastics in Everett, Washington was tasked to help combat the spread of COVID-19 by creating a custom injection molded face…

Read More

May 15, 2020

Youth Apprenticeship Webinars | AJACAJAC hosted two Youth Apprenticeship Webinars to better connect students, parents, and counselors with our next cohorts kicking off Summer 2020. During the webinars we discuss the following: program benefits,…

Read More

February 26, 2020

Our Mission. Their Story.Meet LaDante Weems—a formerly incarcerated youth and now graduate of the AJAC Juvenile Rehabilitation Manufacturing Academy program—tells his story on becoming a full-time employee at Tech Marine. We at AJAC…

Read More

October 25, 2019

AJAC Joins Movement to Get More Women Into ApprenticeshipsThe Aerospace Joint Apprenticeship Committee (AJAC) recently partnered with the Wisconsin Regional Training Partnership (WRTP) on a multi-state effort to encourage more women to enter into technical apprenticeship programs. WRTP…

Read More

October 8, 2019

MFG Day (Manufacturing Day) 2019 | AJAC & Machinists Inc.Take a tour of Machinist Inc in Seattle, Washington as the Aerospace Joint Apprenticeship Committee (AJAC) and Hazen High School (Renton School District) celebrate National Manufacturing Day (MFG Day) 2019.…

Read More

September 23, 2019

Manufacturing Academy Students Develop Financial Stability Through New Wells Fargo PartnershipThe Wells Fargo Foundation, established in the U.S. as a registered 501(c)(3) charitable organization in 1980, is the company’s primary philanthropic funding arm. In 2018, the foundation donated nearly half…

Read More

August 28, 2019

5 Questions With Eytan RaphaelyPlease welcome our first intern since 2014, Eytan Raphaely! Eytan studied marketing communications at the University of Washington and recently graduated this past June. His role at AJAC will focus…

Read More

August 22, 2019

The Boy WonderWhen you walk into AJAC’s Manufacturing Academy at South Seattle College-Georgetown Campus the first thing you’ll notice is the intimidating computer numerical controlled (CNC) and manual machines scattered around the…

Read More

July 16, 2019

5 Questions With John ManningPlease welcome the newest addition to the AJAC family, John Manning. John has been hired as our new Apprenticeship Navigator serving primarily King and Pierce Counties. John will help navigate…

Read More

July 11, 2019

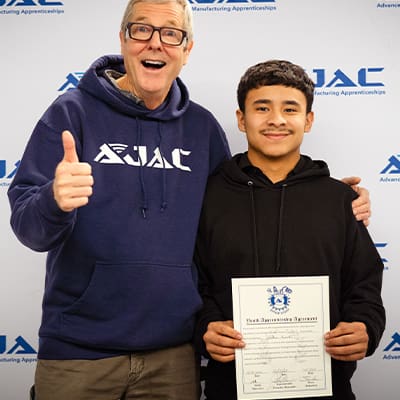

2019 Washington Youth Apprenticeship Signing DayOn June 28, 2019, nearly 100 newly registered Youth Apprentices from across Washington State celebrated the beginning of their apprenticeship at the ShoWare Center in Kent, Washington. Signing Day brought…

Read More

June 18, 2019

AJAC Graduates 79 Apprentices from 48 CompaniesOn June 14, 2019, the Aerospace Joint Apprenticeship Committee graduated 79 registered apprentices representing 48 companies from across Washington State. The apprentices were joined by their family, friends, and colleagues…

Read More

June 6, 2019

An Ordinary Teenager in an Extraordinary ApprenticeshipIt’s six in the morning at Tool Gauge, a Tacoma, Washington manufacturer that creates complex, high-quality plastic and metal parts and assemblies for the global aerospace industry. In walks a…

Read More

June 6, 2019

10 Partnerships & Grants AJAC is Participating InAJAC is thrilled to announce 10 new partnerships and grant funding we have received to help support local partners and workforce development initiatives to advance apprenticeships here in Washington State.…

Read More

April 29, 2019

Apprenticeship vs. College | KING 5 Interviews AJAC Machinist ApprenticeKING 5 News interviewed former AJAC machinist apprentice, Evan Thomas about why he chose to pursue an apprenticeship after high school, even when his friends were off to four-year colleges.…

Read More

February 26, 2019

AJAC Jumpstarts Automotive Youth Apprenticeship ProgramOver the last year, the Aerospace Joint Apprenticeship Committee has partnered with the Northwest Automotive Service Association and Independent Technicians Automotive Committee (ITAC) to council and guide their new General…

Read More

February 18, 2019

AJAC Youth Apprenticeship: Breaking the MoldNew Video Provides a Cinematic Look at Registered Youth Apprenticeship in Washington State. SEATTLE, WA-Washington State Governor Jay Inslee calls it the “supply train for the supply chain”. Aerospace and…

Read More

October 26, 2018

Governor Inslee Visits Cadence Aerospace & Youth ApprenticesDuring a private meeting at Cadence Aerospace, Governor Inslee and his staff met with representatives from the aerospace manufacturer, AJAC and current Youth Apprentices to discuss how the registered Youth…

Read More

October 9, 2018

Manufacturing Day Is More Than Inspiring, It’s FamilyFamily based. Good pay. Good benefits. Those were the three takeaways from students who toured Buyken Metal Products last Thursday as part of a nationwide celebration of manufacturing. Manufacturing Day—occurring…

Read More

July 3, 2018

2018 Youth Apprenticeship Signing Day CeremonyOn June 27, 2018, 67 newly registered Youth Apprentices signed their letter of agreement signifying a commitment to work in the aerospace and advanced manufacturing industries through the Aerospace Joint…

Read More

June 29, 2018

AJAC Celebrates 10th Anniversary with 72 Apprentice Graduates at The Museum of FlightSEATTLE, WA – On Friday, June 22nd, Washington State became home to 72 new aerospace and advanced manufacturing journeymen and women apprentices. The Aerospace Joint Apprenticeship Committee (AJAC) recognized the…

Read More

May 7, 2018

One Year In, AJAC Youth Apprentices Set To Graduate This JuneSeth Hamilton was nearing his 17th birthday and knew he wasn’t going to college. His after-high-school plans did not involve a four-year institution. Rising student loans and lack of finances…

Read More

February 1, 2018

Focus Shifts to Broadening Youth Apprenticeships During 2018 Governor’s Youth Apprenticeship SummitApprenticeships are not an alternative to higher education. It is higher education. This sentiment rang loud and true during the 2018 Governor’s Youth Apprenticeship Summit, which in its second year,…

Read More

January 10, 2018

Governor Inslee Talks Youth Apprenticeship During ‘State of the State’ AddressGovernor Inslee delivered his annual State of the State Address to the Washington State Senate and the State House of Representatives on January 9, 2018. During his speech, Governor Inslee…

Read More

January 9, 2018

New State Audit Report Emphasizes High School CTE Courses with High-Growth IndustriesA new report performance audit for Washington State emphasizes the state’s need to better align high-growth, high-demand occupations with career and technical education (CTE) courses currently offered in high school.…

Read More

January 8, 2018

Machining Apprenticeship Provides Alternative Career PathwayTrevor Mohon, a first-year machinist apprentice at RTC Aerospace – Fife Division, discusses his decision to pursue machining after high school. Trevor explains how this industry has challenged him, the…

Read More

December 13, 2017

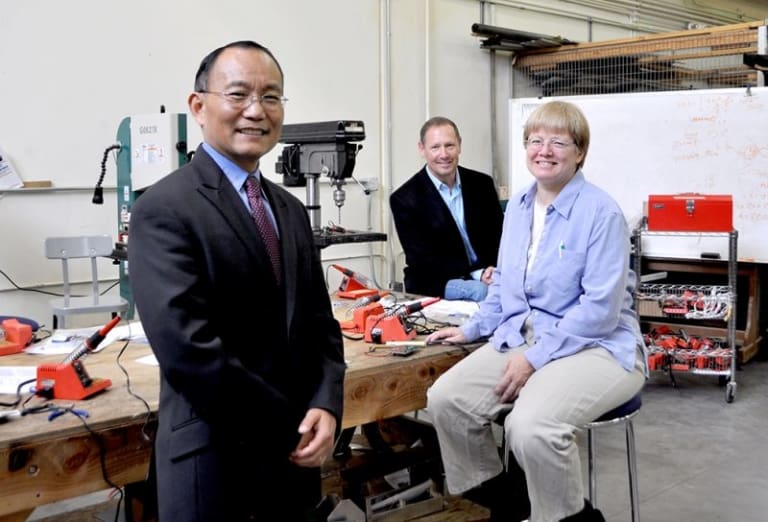

New Advanced Manufacturing Training Center Opens in Kent, WashingtonKent, Washington has a new home for advanced manufacturing. The Advanced Manufacturing Prep (AMP) Training Center was unveiled during a grand opening on December 6th in partnership with the City…

Read More

December 12, 2017

Youth Apprenticeship: The Journey BeginsOn October 16, 2017, Washington State Governor Jay Inslee met with the partners, community organizations and local-area employers to discuss how the first year of Youth Apprenticeship has gone. The…

Read More

October 12, 2017

Manufacturing Day 2017: Opening Doors for the Next GenerationWhat does it mean to work in manufacturing? For some, they see it as an industry booming with innovative ideas and state-of-the-art technology. For others, they see engineers and machinists…

Read More

August 29, 2017

Meet Derek, AJAC’s New Workforce Development CoordinatorAJAC’s new intake specialist will work directly with individuals needing guidance to carve their career in aerospace and advanced manufacturing through job-readiness preparation and pre-apprenticeship training. 1.What is the best part of…

Read More

August 28, 2017

Manufacturing Academy Teaches Job-Ready Skills to Juvenile Rehabilitation Administration StudentsAJAC’s Manufacturing Academy has partnered with Juvenile Rehabilitation Administration and Pioneer Human Services this past year to offer young adults an opportunity to learn job-ready skills through the 12-week, pre-apprenticeship…

Read More

August 7, 2017

Meet Our New Business Developer – Erin Williams!Robin Williams may not come back from the dead, but AJAC’s newest hire has a knack for bringing new programs to life. Meet Erin Williams, our new Snohomish County business…

Read More

July 10, 2017

AJAC Celebrates the Class of 2017To become a journey-level worker signifies a changing of the guard – an ideology that mastery occurs on the job – not solely in the classroom. For AJAC’s 49 apprentice…

Read More

July 7, 2017

Youth Apprenticeship Webinar & PowerPointWashington STEM, Washington State Department of Labor and Industries (L&I) and AJAC gave a joint presentation on all-things Youth Apprenticeship during a live webinar on June 26, 2017. Josie Bryan…

Read More

June 29, 2017

Manufacturing is STEM: Providing Career Connected LearningIn partnership with the Office of the Governor, the Workforce Board, WSU Extension, and the Office of the Superintendent of Public Instruction, Washington STEM traveled across the state to explore…

Read More

May 10, 2017

Meet Jim, AJAC’s Apprenticeship Preparation ManagerHe is a jack of all trades but he has mastered the perfect pizza combo. Meet AJAC’s new Apprenticeship Preparation Manager, Jim Johnson! What’s the best part of your job so…

Read More

May 3, 2017

Yakima Ushers In First Youth ApprenticesYakima’s West Valley High School was given the baton last week to launch their first AJAC Youth Apprenticeship program. High school juniors Trevor Mackey, Osborne Rogers, and Bradley Ethier individually…

Read More

April 17, 2017

AJAC to Participate in Grays Harbor Career Pathway DayOn Monday, April 24, Grays Harbor Youth Works, Greater Grays Harbor, Inc., Aerospace Joint Apprenticeship Committee, and Grays Harbor College worked together to provide North Beach and Lake Quinault High…

Read More

April 10, 2017

Tacoma Celebrates First High School Apprentices During National Signing DayAll eyes were on Pacific Machine last week as the city of Tacoma ushered in a new era of career-connected learning. The decade-old mindset of ‘every student should attend a…

Read More

March 13, 2017

AJAC’s Youth Apprenticeship Featured on City of Tacoma’s ‘CityLine’ TV ShowAJAC’s Youth Apprenticeship program continues to garner attention across our region as the first group of students prepare to begin their apprenticeship in high school. Seth Hamilton, one of our…

Read More

February 16, 2017

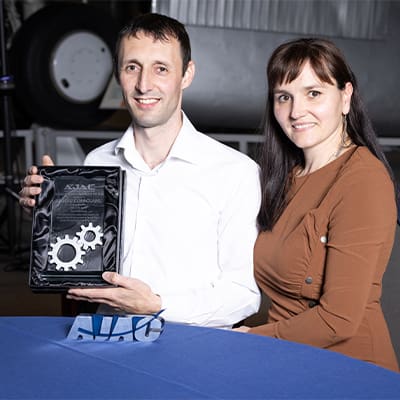

PNAA Selects AJAC for “Inspire Award”AJAC was honored to receive PNAA’s “Inspire” award during the annual Aerospace Conference in Lynnwood, Washington. AJAC’s Executive Director, Lynn Strickland accepted the award during the Aerospace Excellence Awards Banquet.…

Read More

February 15, 2017

AJAC Wins ‘Small Business of the Year’ AwardAJAC’s Exective Director, Lynn Strickland alongside Chamber CEO Andrea Reay On Friday, February 10th, AJAC was selected for the Seattle Southside Chamber of Commerce “Small Business of the Year” Award during…

Read More

January 31, 2017

5 Questions with Danica Hendrickson – Program Manager of Instructionc What will your new role at AJAC include? As Program Manager of Instruction, I will work with subject matter experts, curriculum developers, and instructors to review existing and develop…

Read More

January 26, 2017

KBTC-TV to Feature AJAC and Youth ApprenticeshipFrom left to right: Jody Robbins (L&I), Ron Langrel (Bates Technical College), Lynn Strickland (AJAC), John Altman (Governor’s Office) and Tom Layson (KBTC) The Aerospace Joint Apprenticeship Committee (AJAC) was…

Read More

January 23, 2017

Washington State Approves Governor Inslee’s Youth Apprenticeship ProgramFrom left to right: John Page from Tacoma Public School, Kristi Grassman, AJAC, Lynn Strickland, AJAC, Jesse Cote from IAM 751 and Sandra Husbands, L&I at the Washington Apprenticeship Training Council…

Read More

November 4, 2016

Washington State to Launch First-Ever Youth Apprenticeship Program For High-Demand Industries(From left to right) Governor Jay Inslee, Lynn Strickland and Jesse Milbrath Over the last two years, the Aerospace Joint Apprenticeship Committee, Washington State Department of Labor and Industries, the…

Read More

October 7, 2016

Manufacturing Day Opens Doors for The Next GenerationThe Aerospace Joint Apprenticeship Committee partnered with Training Agent Buyken Metal Products for the third annual Manufacturing Day in Kent, Washington. Over 40 students from Kentridge High School and Kent…

Read More

September 16, 2016

Manufacturing Needs Women – So Let’s Train ThemThe Aerospace Joint Apprenticeship Committee, in partnership with the YWCA and South Seattle College hosted the first-ever Women in Manufacturing Symposium at South Seattle College – Georgetown Campus, highlighting…

Read MoreSeptember 2, 2016

AJAC’s 2016 Summer NewsletterAJAC’s 2016 Summer Newsletter is fresh off the printing press! Grab your copy today and check out what our apprentices, pre-apprentices, and community partners have been up to the last…

Read More

August 29, 2016

AJAC’s ‘Manufacturing Academy’ Goes Full-Throttle With ‘Earn While You Learn’ ModelInternships can be a grueling yet necessary step most of us endure before we are accepted in the working world. In manufacturing, internships are far-and-few between – but one program…

Read More

August 29, 2016

Disadvantaged Youth Learn Aerospace While in High School (Video)In 2012, the median age in manufacturing was nearly 45 years old, a number that is expected to rise continually over the next decade. An influx of young talent into…

Read More

August 29, 2016

Women in Manufacturing SymposiumJoin us for this forum and networking event introducing women to career and training opportunities in the exciting and dynamic field of advanced manufacturing. Hear from a panel of women…

Read More

August 29, 2016

Apprenticeships Can Change Lives, AJAC Grad SaysAJAC Machinist Graduate, Irwin Downes shaking hands with IAM 751 Organizer, Jesse Cote TUKWILA — Apprenticeships have the power to change lives. That’s the message graduates of the Aerospace Joint…

Read More

August 29, 2016

Meet AJAC’s New On-the-Job Training Advisor, Bri Durham!What is your proudest career moment? I worked on 1.5 million dollar grant that was awarded by OJJDP to Pioneer Human Services and JJRA to run a pilot AJAC Manufacturing…

Read More

August 29, 2016

Senator Patty Murray Visits Manufacturing AcademySenator Patty Murray stopped by the Seattle Manufacturing Academy program on August 9th to discuss how the Workforce Innovation and Opportunity Act (WIOA) has helped undeserved and disadvantaged individuals to…

Read More

August 29, 2016

Inspiration in Machinist’s Training at Senior Aerospace AMT[vimeo src=167495188] The Victory Series | Episode 12 Featuring Matt Washburn of Senior Aerospace AMT from 4th Avenue Media on Vimeo. How a business leader is keeping manufacturing and machining…

Read More

August 29, 2016

Tommy – Boeing Tech, Pioneer IndustriesTommy grew up in a big family with three brothers and two sisters in Grays Harbor on Washington State’s coast. He was involved in school and sports as a young…

Read More

August 29, 2016

Aeroplastics Featured on KING 5 NewsAJAC’s Training Agent Aeroplastics was recently interviewed by Seattle’s KING-TV to highlight their efforts in creating parts for industries outside of aerospace. Watch the clip above and read more…

Read More

August 25, 2016

AJAC Molds New Plastic Process Technician Apprenticeship ProgramIn the United States, the plastics industry is the third-largest manufacturing industry. The outlook is strong nationally, from injection molding companies to high-demand 3D printing, plastics companies are expecting a…

Read More